In addition to Weibo, there is also WeChat

Please pay attention

WeChat public account

AutoBeta

2024-11-21 Update From: AutoBeta autobeta NAV: AutoBeta > News >

Share

AutoBeta(AutoBeta.net)02/12 Report--

In the Ningde era, which had just announced the signing of a battery cooperation agreement with Tesla, it issued a risk notice in two consecutive days, noting that the impact of the cooperation agreement with Tesla on the company's future operating performance was still uncertain. In less than a month, there were media reports that Tesla was building his own battery production line to reduce battery costs.

It is understood that Tesla is building a pilot battery production line in Fremont, USA, and is designing his own battery production equipment. This will be the first time for Tesla to produce his own batteries, and will become the first batch of Tesla's home-made batteries.

Moreover, according to Tesla's latest recruitment information, Tesla's battery manufacturing and battery engineering team is also recruiting talents in the European region. it also revealed new plans for battery manufacturing expansion in Europe: positions responsible for planning and managing new battery manufacturing and equipment engineering projects, the need to promote the development and deployment of new manufacturing equipment and processes, as well as the planning and implementation of new battery manufacturing expansion plans in Europe.

However, according to foreign media reports, Tesla's plan to set up a super factory near Berlin to produce batteries has been confirmed, but it is not clear whether he plans to produce batteries in cooperation with battery manufacturers or independently. But at present, it seems that Tesla is more and more likely to produce his own batteries.

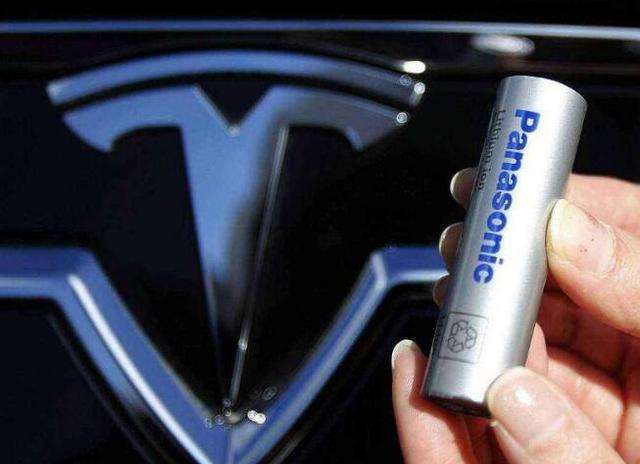

Although the battery manufacturers that have announced successful cooperation with Tesla are Panasonic, LG and Ningde era, Tesla has been saying that he wants to build his own battery factory and is preparing for the layout in order to further reduce its battery cost.

At the annual shareholders' meeting in June last year, Musk announced plans to "expand battery production and reduce unit battery costs." And in October of the same year, Tesla quietly acquired Hibar, a Canadian battery maker. On January 29th, Tesla reviewed his battery plan again and declared that "Tesla will not raise capital, but will focus on increasing battery production capacity and reducing battery costs."

On January 30th, Tesla CEO Elon Musk mentioned that he would become a new partner with LG and Ningde Times in the fourth quarter 2019 earnings conference call. A few days later, Ningde Times, a power battery supplier, issued an announcement on the morning of February 3, confirming that it had signed an agreement with Tesla to supply Tesla with lithium-ion power battery products, which would start in July.

However, Ningde Times issued two announcements about Tesla in the morning and evening on February 3, both of which mentioned that there was still uncertainty about the impact of the cooperation agreement with Tesla on the company's future operating results. Obviously, this makes a leading battery manufacturer in the country and even around the world seem a little conservative.

At present, the battery cores of Tesla's models are made by Panasonic and LG, of which Model S and Model X use Panasonic batteries, while from the catalogue of recommended models for the promotion and application of new energy vehicles published in December last year, the domestic Tesla Model3 uses Panasonic and LG chemical batteries at the same time.

With the rising sales of Tesla models, the demand for batteries is increasing. But Tesla once disliked Panasonic's insufficient battery supply, saying it was a "fundamental constraint" on its electric vehicle production, so he had two other battery LG and Ningde era cooperation plans, but learned from the cooperation agreement between Tesla and Ningde era that the two supply agreements are relatively small. So at present, it seems that although Tesla has signed supply agreements with three battery suppliers, it may be a transitional measure adopted by Tesla to wait for his battery factory to achieve mass production.

With the rapid development of new energy vehicles around the world, it seems that every automobile company wants to control the battery technology, which is the most important part of the new energy vehicle. The power battery is the core component of the electric vehicle, and its cost accounts for 40% of the whole vehicle. 50%, so it is concerned by more and more car companies, so that many car companies have launched strategic cooperation with power battery manufacturers or built their own battery factories. To seek their own long-term development.

Welcome to subscribe to the WeChat public account "Automotive Industry Focus" to get the first-hand insider information on the automotive industry and talk about things in the automotive circle. Welcome to break the news! WeChat ID autoWechat

Views: 0

*The comments in the above article only represent the author's personal views and do not represent the views and positions of this website. If you have more insights, please feel free to contribute and share.

© 2024 AutoBeta.Net Tiger Media Company. All rights reserved.