In addition to Weibo, there is also WeChat

Please pay attention

WeChat public account

AutoBeta

2024-11-17 Update From: AutoBeta autobeta NAV: AutoBeta > News >

Share

AutoBeta(AutoBeta.net)02/21 Report--

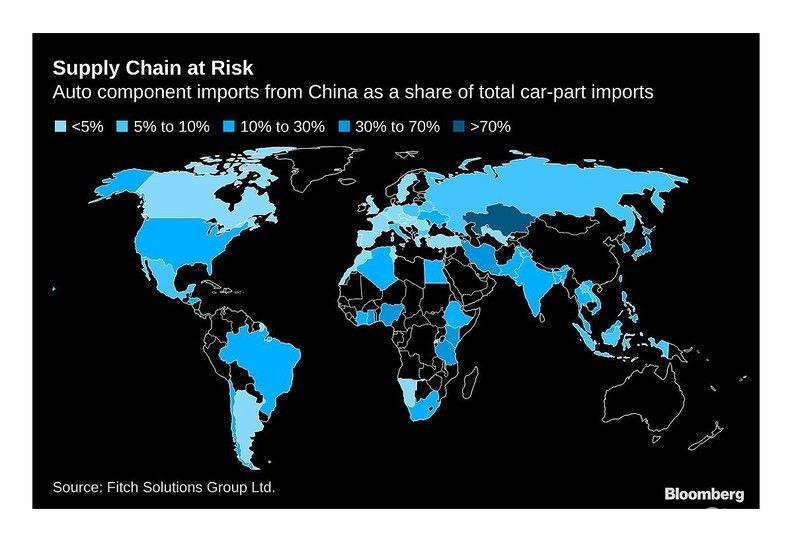

Nissan is preparing for possible production disruptions at factories in Europe and the United States due to parts shortages caused by the spread of the COVID-19 epidemic in China, according to Bloomberg, citing people familiar with the matter. as a result, Nissan's entire supply chain has been seriously damaged.

Nissan currently produces nearly 800 auto parts from Hubei Province, and Nissan will face a shortage of most parts if factories in Hubei Province fail to resume production after the 21st, according to people familiar with the matter.

Due to a shortage of spare parts, Nissan is likely to stop production in some parts of the Japanese car market on February 23, followed by a suspension of production at its plant in Malaysia. If parts makers delay production further, the Japanese car company could further suspend production at factories in the US, Mexico, the UK, Spain, Russia and India.

According to a circular issued by the Hubei Provincial people's Government, all kinds of enterprises in Hubei Province should resume work no earlier than 24:00 on March 10. From this point of view, Nissan has basically decided to stop production at its factories in all major markets.

Hubei Province is not only the hardest hit area of the epidemic, but also an important manufacturing center of domestic auto parts manufacturing. It is understood that Wuhan alone has seven complete vehicle manufacturing companies, 12 automobile final assembly factories and more than 500 parts enterprises, and Hubei Province happens to be the headquarters of the joint venture between Nissan and Dongfeng Motors, which also makes the Japanese car company more vulnerable to parts supply disruptions than other car companies.

In fact, Nissan announced some of its production lines in Kyushu in southwestern Japan on February 14, and production at other factories in Japan will be suspended on February 23. There is still no specific plan for when to return to work, and it is still very difficult to resume production within a short period of time.

Nissan is also actively communicating with the Chinese government, hoping to resume production as soon as possible, but only 58% of suppliers said they could resume production in mid-February, and other enterprises could not resume work without government approval. even at the beginning of production, only half of the 58% have returned to work, and the actual resumption rate is not high.

Obviously, the COVID-19 epidemic makes this already difficult Japanese car company into a more serious situation. According to Nissan's financial results for the third quarter released a few days ago, operating income in the first three quarters fell 12.5 per cent year-on-year to 7.5073 trillion yen, operating profit fell 82.7 per cent to 54.3 billion yen, while net profit fell 87.6 per cent to 39.3 billion yen. Of this, the company reported a net loss of 26.09 billion yen in the third quarter, the first quarterly net loss in nearly a decade.

In terms of sales, Nissan declined to varying degrees in 2019 in the Chinese market, the American market, the European market and the Japanese market, by 1.1%, 9.9%, 17.2% and 7.8%, respectively.

In the context of falling profits, cost-cutting has become the only measure that Nissan has to take. Nissan plans to cut 12500 jobs worldwide, which will be completed by March 31, 2023. In addition, the company will cut its marketing budget and streamline its product line, involving a total of 60 models from Infiniti, Nissan and Datsan.

In fact, in addition to Nissan, many multinational car companies also have to stop production because of a broken supply chain. Jaguar Land Rover plans to reopen next week, but a shortage of parts may also lead to production at British factories. Jaguar Land Rover had to airlift Chinese-made parts to the UK in suitcases, but they met only two weeks of production. Jaguar Land Rover CEO Schweder said production was safe this week and next week, but parts would be scarce in the third week.

South Korea's Hyundai first plant in Ulsan faces another partial shutdown just one day after resuming work. The second plant in Ulsan will stop work for one day on the 21st, and the Yashan plant may also face another shutdown. The shutdown caused by insufficient supply of spare parts in China may continue. In addition, automakers such as Toyota, PSA and Volvo said that the domestic parts supply chain had been disrupted by the epidemic and would make plans to monitor possible risks.

Welcome to subscribe to the WeChat public account "Automotive Industry Focus" to get the first-hand insider information on the automotive industry and talk about things in the automotive circle. Welcome to break the news! WeChat ID autoWechat

Views: 0

*The comments in the above article only represent the author's personal views and do not represent the views and positions of this website. If you have more insights, please feel free to contribute and share.

© 2024 AutoBeta.Net Tiger Media Company. All rights reserved.