In addition to Weibo, there is also WeChat

Please pay attention

WeChat public account

AutoBeta

2024-11-17 Update From: AutoBeta autobeta NAV: AutoBeta > News >

Share

AutoBeta(AutoBeta.net)03/22 Report--

Recently, some people in the media asked about the specific safety and quality of the main swing arm using "composite materials" in view of the ideal ONE model of the ideal car. It is reported that Tesla also uses the same type of material, but the ideal ONE security issue has been questioned.

According to the questions raised by the car commentator and the actual picture, we can see that the material of the lower main swing arm of the ideal ONE does look very similar to plastic parts, so that many auto netizens think that the body of an ideal ONE vehicle with more than 2 tons is made of plastic parts, which undoubtedly has a great guess on the safety issue.

In this regard, the official Weibo of ideal Automobile has also been clarified, and some suspected suppliers have revealed that this is a more cutting-edge composite material at present, and Tesla's model is also designed in this way.

The lower arm of the car, also known as the lower suspension of the car, is an important part of the automobile. Although the part is small, it plays a very important role in supporting the car body, and constitutes the suspension system together with the shock absorber and spring of the vehicle. At present, the commonly used materials for the lower arm of vehicles are cast iron, steel, aluminum alloy and other metal materials.

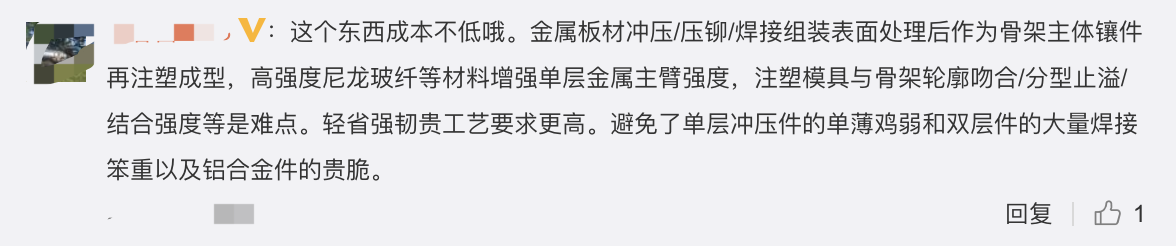

Removing the ideal ONE lower arm shows that the interior of the ideal ONE lower arm is still a steel stamping part, which is made of steel from the upper layer, while the lower layer is made of "PA6+GF5O" nylon / fiberglass composites. PA6 polyurethane is one of nylon and is reinforced with 50% glass fiber, so it does look like a plastic part from the surface.

The advantage of PA6 is to show high strength, good rigidity, high wear resistance, and so on. It can also be used freely in the environment of-40 ℃ ~ 100 ℃. It can be seen that the bearing capacity is quite good. Compared with cast iron, copper, aluminum, and other metal materials, PA6DE is less rigid than metal, but the strength is higher than metal, so from a variety of data, various properties of PA6 are equivalent to metals.

There are other advantages of using this material, among which weight loss and corrosion resistance are also valued by ideal cars. At present, the weight of the hem arm of the ideal ONE is about 3.2kg, which is equivalent to the weight of aluminum. in order to reduce the weight of the whole vehicle, the ideal car is also considered from many aspects, including that the body-in-white is not made of all-aluminum alloy. At the same time, the ideal also means that there is a certain cost in using the composite, because the cost of the composite is even higher than the welding cost of aluminum alloy castings and steel plates, but lower than that of forged aluminum alloy.

However, for some netizens, no matter how plastic is plastic, it is always not as good as the traditional metal parts, and there is still a lot of uncertainty about the stability and the later changes due to the influence of the environment.

Of course, many netizens who know about this new type of composite material think that we should treat the new material reasonably. The reason why we choose such a technology, the ideal car is also considered in many ways, so that all aspects of the vehicle have a better tradeoff.

In fact, this kind of composite material has been used in military industry for a long time, including many aviation fields. According to Tesla's models, this composite material is used in Tesla's Model Y, Model S and Model 3 models.

In addition, the ideal car has also carried out 165000 km chassis strengthening test and 1.5 million km road test for the ideal ONE, during which no problems with the lower swing arm of the ideal ONE have been found. It can be seen that this new material can still stand a certain test. But the composite material is only a new material at present, with the passage of time, more and more automobile companies will consider it comprehensively, of course, the cost is one of the main reasons.

However, it is more time-tested to adopt new materials. For this reason, what do netizens think of the use of traditional metal parts or composite materials?

According to the latest data from ideal cars, the ideal ONE was only 269 units in February, down 77% from the previous month. However, according to the initial public sales data of ideal cars in January, January delivery reached 1180 units, second only to the ES6.

Welcome to subscribe to the WeChat public account "Automotive Industry Focus" to get the first-hand insider information on the automotive industry and talk about things in the automotive circle. Welcome to break the news! WeChat ID autoWechat

Views: 0

*The comments in the above article only represent the author's personal views and do not represent the views and positions of this website. If you have more insights, please feel free to contribute and share.

© 2024 AutoBeta.Net Tiger Media Company. All rights reserved.