In addition to Weibo, there is also WeChat

Please pay attention

WeChat public account

AutoBeta

2024-11-18 Update From: AutoBeta autobeta NAV: AutoBeta > News >

Share

AutoBeta(AutoBeta.net)08/18 Report--

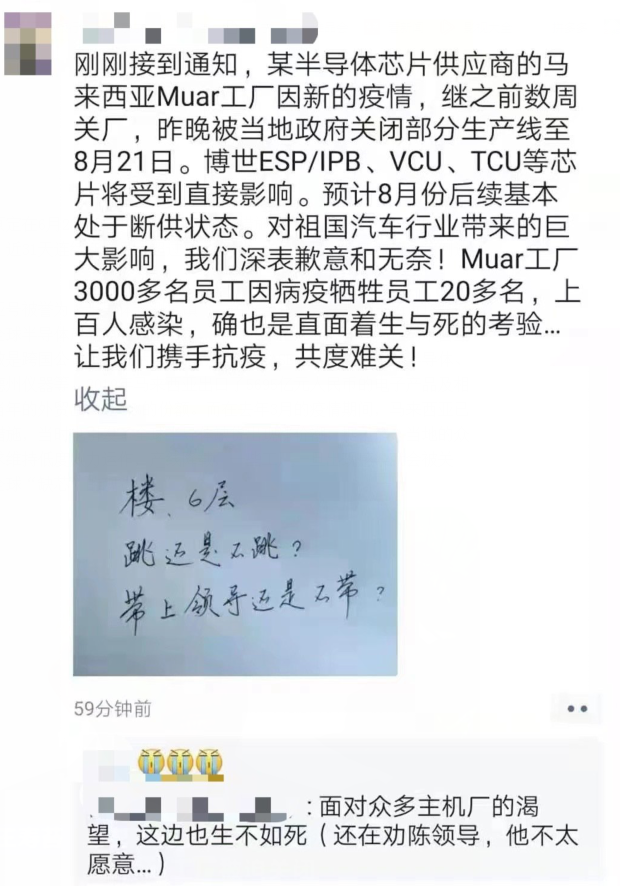

On August 17, Xu Daquan, executive vice president of Bosch (China) Investment Co., Ltd., said through Wechat moments that due to the serious epidemic in Malaysia, the Malaysian Muar factory of a semiconductor chip supplier closed down a few weeks ago and was again asked by the local government to shut down part of the production line until August 21, which will directly affect Bosch ESP/IPB, VCU, TCU and other chips. It is expected that the supply will be cut off in August. It will have a great impact on the domestic automobile industry.

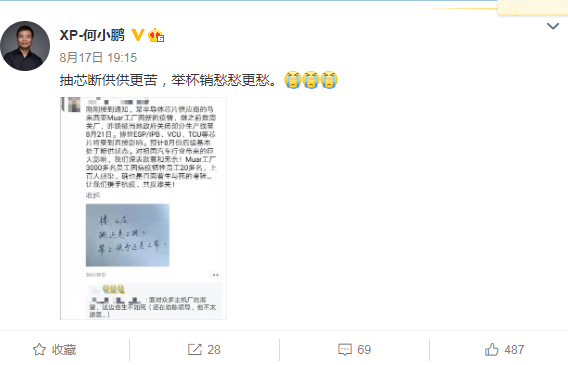

In response to this news, Xiaopeng Automobile founder he Xiaopeng also said in an article, "it is more bitter to cut off supply, and to raise a glass to sell sorrows." "We are cooperating with China and overseas," he Xiaopeng said in an interview with the media. "A car now has about 1700 chips and needs a lot of chips. Xiaopeng will do a lot of things in the future." Even though there are many partners on the chip, he Xiaopeng is not optimistic about the current situation, saying that for the automobile supply chain, August 2021 may be the most challenging month since the 2020 epidemic. The reason is that after the shortage of batteries and chips, multiple outbreaks will increase the pressure on the supply chain.

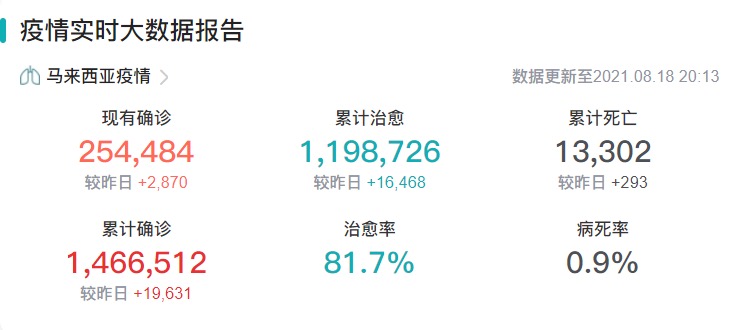

Recently, the epidemic situation in Malaysia continues to worsen. In order to control the COVID-19 epidemic, Malaysia has been closed for two weeks since June 1. According to CCTV News, the "total blockade" originally scheduled to end on June 28 will be extended again. At present, the number of COVID-19 patients in Malaysia is still growing, with more than 10000 new patients in a single day for 31 consecutive days. On August 17th, the number of new confirmed cases reached 19600.

According to the media, the ESP of Bosch's cut-off chip is the body electronic stability system, IPB is the intelligent integrated braking system, VCU is the vehicle controller, and TCU is the automatic transmission control module of the car. Bosch, the world's largest auto parts supplier, has suffered a supply cut in key chip areas, which will undoubtedly make the auto industry, which is already seriously short of cores, even worse.

It is worth mentioning that Malaysia is known as the "semiconductor closed testing center", accounting for nearly 13% of the global semiconductor packaging market. It is the seventh largest exporter of semiconductor products in the world, and about 50 global semiconductor giants have set up closed testing factories in Malaysia, most of which are multinational companies, including AMD, NXP, ASE, Infineon, Italian and French Semiconductor, Intel, Broadcom, Micron, Texas Instruments and so on. Malaysia exported 569.5 billion yuan of electronic products and related components in 2019, accounting for nearly 40 per cent of the country's foreign trade exports that year. During the epidemic in March last year, Malaysia had already taken a "ban" measure, which also triggered a wave of price increases in global semiconductor shortages. It is understood that the production lines of many local semiconductor factories are required to maintain low-level human operation, production lines are reduced, and some factories will be closed in the event of infection. This may further aggravate the global "lack of core" situation.

According to the data of AutoForecast Solutions, as of August 9, the global automobile production loss caused by chip shortage has reached 5.853 million, of which North America and Europe have the largest loss, 1.874 million and 1.746 million respectively, followed by China, 1.122 million. AutoForecast Solutions predicts that the final loss of global car production for the whole year could rise further to 7 million vehicles. Of course, the continuing impact of the Malay epidemic is not only an impact on the automobile industry chain, but also many industries in the consumer electronics industry, such as mobile phones. In 2021, a number of car companies have stopped production and reduced production due to "lack of core", including Volkswagen, Toyota, Nissan, Ford, Suzuki, and other car companies have announced to stop production, reduce production to deal with the core shortage problem.

According to a forecast released by HIS, the number of light vehicles reduced by chip shortages reached 672000 in the first quarter of 2021 and increased to 1.3 million in the second quarter of 2021. This also means that the problem of lack of core will continue to affect the automobile industry for some time in the future. Previously, Infineon and NXP, the world's two largest automotive chip makers, have said that the supply and demand of chips will not be balanced until the middle of next year. A few days ago, Sun and Moon, which provides closed testing services for chip manufacturers, also believes that the chip problem will continue to be in shortage in 2022. At present, the shortage of chip supply will still be a challenge for many industries.

Welcome to subscribe to the WeChat public account "Automotive Industry Focus" to get the first-hand insider information on the automotive industry and talk about things in the automotive circle. Welcome to break the news! WeChat ID autoWechat

Views: 0

*The comments in the above article only represent the author's personal views and do not represent the views and positions of this website. If you have more insights, please feel free to contribute and share.

© 2024 AutoBeta.Net Tiger Media Company. All rights reserved.