In addition to Weibo, there is also WeChat

Please pay attention

WeChat public account

AutoBeta

2024-11-17 Update From: AutoBeta autobeta NAV: AutoBeta > News >

Share

AutoBeta(AutoBeta.net)09/06 Report--

When will the problem of "lack of core" be solved? The problem of lack of core has not stopped since it broke out at the end of 2020, but the situation is becoming more and more serious. The chip ordering cycle used to be almost three quarters, but now it has been extended to a year or more, said one chip industry employee.

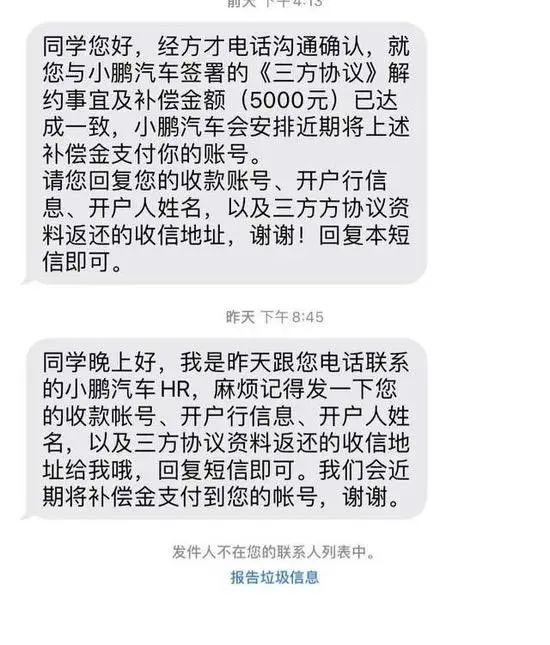

Affected by the lack of core, the pick-up cycle of most car brands has also been postponed accordingly. Some media interviewed the experience centers of several car companies in Beijing. A salesperson at a Xiaopeng car experience center in Beijing said: the chips will become more and more tense, so it is recommended to book the car as early as possible. A salesperson at an ideal experience center in Beijing said: "before, the pick-up cycle of our store was two weeks, but now it has been extended to seven weeks, mainly due to the shortage of chips." The salesperson of a Weima experience center in Beijing also revealed: "at present, the supply of chips is really tight, so manufacturers try their best to provide them with models like the W6." A salesperson at a SAIC-Volkswagen 4S store in Beijing said: "there are plenty of ID.4 X and ID.6 X electric cars at present, but if you want to install a heat pump, it will take a long time to pick up the car because of the shortage of chips. in addition, only a small number of fuel models have a very small number of existing cars."

The shortage of chips has led to a shortage of inventory among dealers. Many dealers said that they could not bring up the car from the manufacturer, and even sold the exhibition car. Geely Electric cars are also affected by the global lack of core, Geely Electric cars are also affected by the global lack of core, Geometry brand cannot deliver 10, 000 orders, and some dealers even start selling exhibition cars, Geely Group CEO Gan Jiayue said at Geely's 2021 interim results conference on Aug. 18. On August 17, the Great Wall tank brand officially released a message saying, "if an order is placed now, it is estimated that the delivery cycle of the tank 300 is roughly 4-5 months." Prior to this, the tank brand had stated that "due to chip supply problems, shortages of key components such as ESP and four-wheel drive controllers have led to the release of factory capacity that has been upgraded."

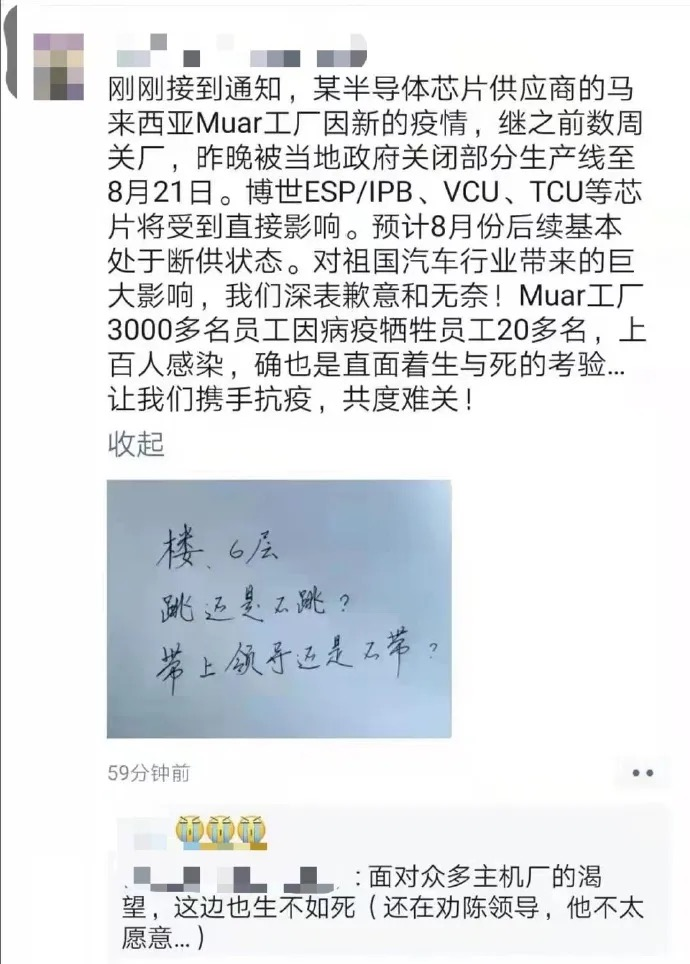

Earlier, Bosch (China) Investment Co., Ltd. executive vice president Xu Daquan said through the social platform that a semiconductor chip supplier's Malaysian Muar factory due to a serious epidemic in Malaysia, following the factory closure in the previous few weeks, was again asked by the local government to shut down part of the production line until August 21, Bosch ESP/IPB, VCU, TCU and other chips were directly affected, and it is expected that the supply will be cut off in August. It will have a great impact on the domestic automobile industry. According to relevant data, the semiconductor chip supplier referred to in Xu Daquan's article is Italian Semiconductor. The chip products of Italian and French semiconductors play an important role in the auto parts industry. For example, the overall demand coverage of auto parts based on L9369-TR chip materials in Chinese mainframe factories reached 7.5 per cent, and the shortage will affect the production of nearly 900000 vehicles in China in August.

It can be seen that due to the impact of the epidemic in Malaysia, some of its chip bases are in a "paralyzed" state, further aggravating the global core shortage crisis. At present, the global chip market, a "core" is difficult to obtain is the norm in the current market. In the face of rising chip prices, car companies can only accept it. Some media reported earlier that in order to get such tight chips such as the MCU, many car companies even spend a lot of money to buy them, and some are even willing to pay the cost of next year's order to the chip supplier in advance.

According to Auto Forecast Solutions statistics, by August 9 this year, the worldwide production reduction caused by the chip shortage has reached 5.85 million, of which the Chinese market has reduced production by 1.122 million. It is estimated that the global car production will be reduced by more than 7 million in 2021, and this "chip shortage" may last until next spring. Cui Dongshu, secretary general of the Carriage Association, predicted that with the sharp increase in industrial investment, the strong chain complement chain of the independent chip industry chain is constantly improving, and it is expected that oversupply will inevitably be the reality of the chip market next year, so it is necessary to rationally respond to the reality of chip shortage. at the same time, we should also reasonably guide the retention of orders to meet the restorative growth of the car market in the fourth quarter and even next year.

Welcome to subscribe to the WeChat public account "Automotive Industry Focus" to get the first-hand insider information on the automotive industry and talk about things in the automotive circle. Welcome to break the news! WeChat ID autoWechat

Views: 0

*The comments in the above article only represent the author's personal views and do not represent the views and positions of this website. If you have more insights, please feel free to contribute and share.

© 2024 AutoBeta.Net Tiger Media Company. All rights reserved.