In addition to Weibo, there is also WeChat

Please pay attention

WeChat public account

AutoBeta

2024-11-17 Update From: AutoBeta autobeta NAV: AutoBeta > News >

Share

AutoBeta(AutoBeta.net)09/20 Report--

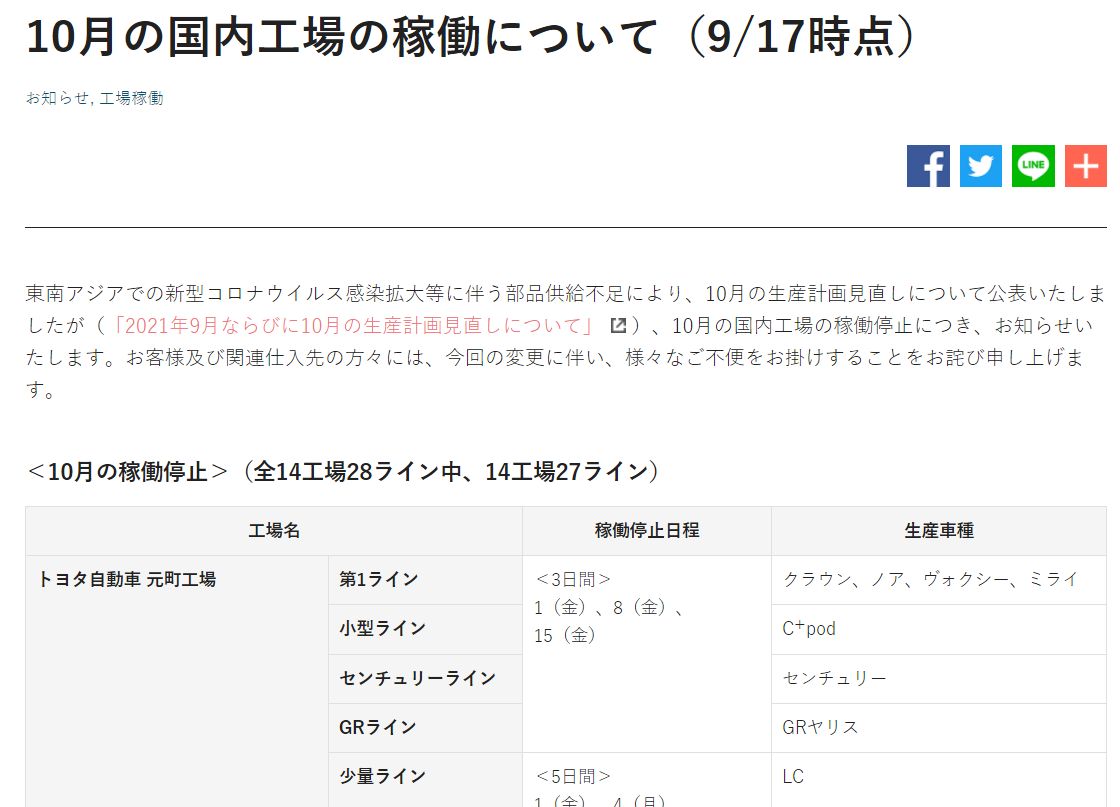

Japan's Toyota Motor Co., Ltd. said on its website that a total of 27 production lines at 14 factories in Japan will cease operation in October due to a shortage of spare parts caused by the epidemic in Southeast Asia, CCTV Financial reported. According to Toyota's latest announcement, the second production line at the Takaoka plant, which produces RAV4 and Harrier, will be suspended for five days; the third production line at the Taiyuan plant, which produces Lexus LS, IS, RC, RC F and NX models, will be suspended for eight days; the first production line at Miyada plant, which produces Lexus NX and RX, will be suspended for 7 days; and most seriously, the Yoshihara plant, which mainly produces Land Cruiser and Lexus LX, will stop production for 11 days.

In August, Toyota announced that global production in September would fall from 900000 originally planned to 540000 (140000 in Japan and 220000 overseas) due to a shortage of spare parts caused by the COVID-19 epidemic in Southeast Asia. As the COVID-19 epidemic continues to spread in Southeast Asia, Toyota's auto parts supply has been further affected. Toyota expects to cut global production by about 330000 vehicles in October (150000 in Japan and 180000 overseas), equivalent to 40% of the original production plan.

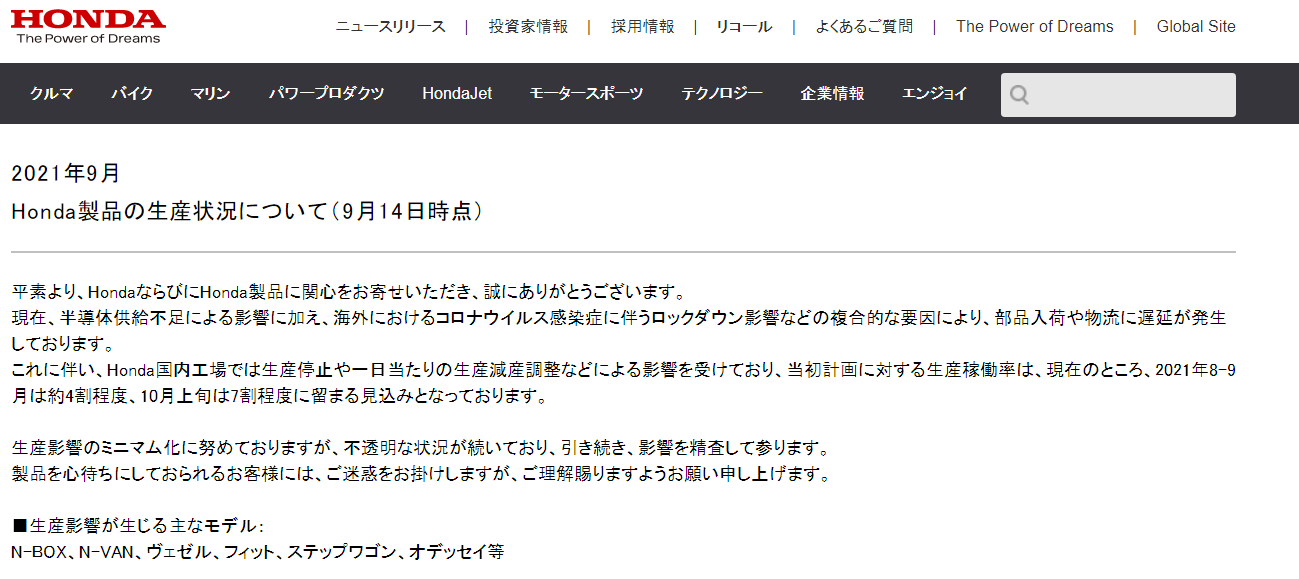

In addition to Toyota, other Japanese models are also suffering from parts supply problems, have announced to cut production or stop production. Honda posted on its website that parts shipments were delayed by a shortage of semiconductor chips and the overseas novel coronavirus epidemic. Honda's domestic plants were affected by factors such as shutdowns and reduced daily production, and capacity utilisation would remain at about 70 per cent in October.

Why does the epidemic in Southeast Asia continue to affect the production of car companies? It is understood that Malaysia currently has more than 50 semiconductor factories set up locally, including Intel, Infineon, Italian Semiconductor, NXP, Texas Instruments, on Semiconductor and other major chip supply giants. Malaysia's closed test capacity accounts for about 13% of the global closed test capacity. On the other hand, automotive MLCC, chip resistors, solid-state capacitors, aluminum capacitors and other chip production capacity will be affected to varying degrees.

Due to parts shortages caused by the spread of the COVID-19 epidemic in Southeast Asia, six large Japanese automakers, including Toyota, will cut production by more than 1 million vehicles this fiscal year (April 1, 2021-March 31, 2022). This is equivalent to 15% of the total passenger car production of Japanese automakers in the last fiscal year, of which Suzuki is expected to cut production by 350000 vehicles, ranking first among Japanese automakers.

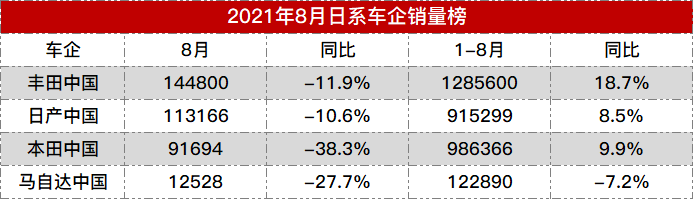

The chip shortage has also affected overseas sales of Japanese automakers. According to the latest statistics, six Japanese car companies, including Toyota, lost about 370000 vehicles in China in August, down 20.8 per cent from the same period last year. According to previous statistics, Toyota's sales in China in August were 144800, down 11.9% from a year earlier; Nissan China was 113200, down 10.6% from a year earlier; and Honda China was 92000, down 38.3% from a year earlier.

At present, the chip shortage not only affects the domestic production in Japan, but also has a certain impact on the production and sales of the Chinese market, but compared with Japan, the chip shortage has less impact on the Chinese market.

In fact, under the double pressure of COVID-19 epidemic and chip shortage, the global automobile industry is facing pressure. At the 2021 Munich Auto Show, a number of German auto company leaders unanimously predicted that the shortage of the global chip supply chain would continue for 6 to 18 months.

Daimler CEO Ola Kaellenius said on Sunday that the surge in demand for semiconductor chips means it may be difficult for the automotive industry to procure enough semiconductor chips from next year to 2023, but supply shortages should not be as severe by then. Oliver Zipse, chief executive of BMW, said today that supply chain tensions are expected to continue into 2022, at least for the next 6-12 months. Volkswagen CEO Herbert Diess said on Monday: "because of the strong demand for semiconductors, Volkswagen may still be in shortage in the coming months or even years. The Internet of things is developing, and it will take time to increase production capacity. This could be a bottleneck in the coming months and years. "

Eason Huamai, a well-known global market analysis company, released a report saying that the global semiconductor shortage will reduce the world automobile industry's production by as much as 7.1 million vehicles this year, and the chip supply disruption caused by the COVID-19 epidemic will extend the difficulties faced by the automobile industry into next year. The global chip shortage will not ease until the second half of 2022.

Welcome to subscribe to the WeChat public account "Automotive Industry Focus" to get the first-hand insider information on the automotive industry and talk about things in the automotive circle. Welcome to break the news! WeChat ID autoWechat

Views: 0

*The comments in the above article only represent the author's personal views and do not represent the views and positions of this website. If you have more insights, please feel free to contribute and share.

© 2024 AutoBeta.Net Tiger Media Company. All rights reserved.