In addition to Weibo, there is also WeChat

Please pay attention

WeChat public account

AutoBeta

2024-11-17 Update From: AutoBeta autobeta NAV: AutoBeta > News >

Share

AutoBeta(AutoBeta.net)02/03 Report--

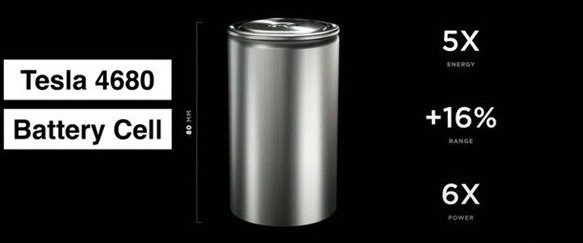

Panasonic's financial director confirmed today that Panasonic is renovating a battery factory to prepare for 4680 production and will begin trial production of 4680 electric car batteries in April. This battery, which was mentioned by Tesla in 2020, claims that the single energy can be increased by 5 times, and the vehicle mileage can be increased by 16%. And Panasonic also responded that as Tesla has a strong demand for this battery, it will give priority to meeting Tesla's requirements after mass production. According to Panasonic's financial data, Tesla's business accounts for about 60 per cent of Panasonic's energy business revenue, which earned $1.69 billion in the last quarter of last year. Tesla contributed 1 billion US dollars, Panasonic will of course give priority to protect the needs of this largest customer.

In a conference call after Tesla released his financial results a few days ago, Tesla CEO Musk confirmed that 4680 has been deployed on the prototype car. At Tesla's Texas factory, it is already using 4680 batteries to produce Model Y, but it needs to complete the relevant product certification before it can be delivered to the market.

Tesla's supporting factory in Texas will also produce this new type of battery, and the number of factories producing batteries will be further increased when the production technology is mature. Along with other suppliers, including Panasonic, Tesla will also be supplied with 4680 batteries. As a result, at the earnings meeting, Drew Baglino, Tesla's vice president of engineering and technology, said that the supply of 4680 batteries would not be restricted this year, and that the first batch of Model Y with 4680 batteries was expected to be delivered by the end of the first quarter of 2022.

Tesla is eagerly looking forward to using 4680 batteries, as are some of Tesla's new car owners, which is easy to understand because it can add some mileage. But in fact, when to use the 4680 battery will bring more benefits to Tesla than to the car owner. In 2020, Tesla revealed to the outside world this new type of 4680 battery, which is a larger new cylindrical battery with a diameter of 46 mm and a height of 80 mm, so it is named 4680 battery, also known as electrodeless ear, with a 16% increase in power and a 14% drop in cost.

In October 2021, Panasonic showed off a prototype of the battery, which is five times larger than the one Tesla used earlier, which is the secret of the increase in power. By contrast, the battery density of 4680 has only increased by 15%, but the use of larger batteries will naturally significantly reduce the number of batteries used in vehicles. The 2170 battery pack currently used by Tesla consists of more than 4000 small cells, and 4680 can reduce this number to 800. this means that the production time of battery equipment is greatly reduced, combined with Tesla's integrated body forming technology. the car body is simplified into several modules, which is of great significance to Tesla at the present stage.

Tesla ranked first in electric vehicle sales in the world with 936172 vehicles in 2021, more than double that of the same period last year. Tesla ranked first with sales of 499535 vehicles in 2020. Tesla's global sales are expected to continue to grow this year. Tesla's delivery speed is limited by the factory's production capacity, and many car buyers will have to wait for several months. just last week, November bookings just mentioned cars. At present, Tesla produces Model 3 and Model Y at the Fremont factory in the United States and the Shanghai factory in China, and their new factory in Berlin, Germany, has just begun to be put into use in these two months. Once the problems of Tesla's production capacity and delivery time are solved, then Tesla has the energy and attracts more orders. Therefore, bicycle production time has been a priority problem that Tesla has been trying to solve when he ran out of capacity in the past year or two. This includes the use of larger batteries, simpler body production technology, faster paint drying and minimizing the number of chips used, which is why all car factories have been forced to stop production in the past year due to lack of chips. on the contrary, Tesla can take advantage of the opportunity to generate power. In recent days, several new cars that Tesla has just produced are waiting at the Shanghai wharf to be shipped to Israel, Greece and Britain.

According to information revealed by Tesla at the factory open day in Berlin last year, 4680 batteries will appear in the form of structured batteries. The battery and the chassis are completely integrated, and the upper cover of the battery is the floor of the carriage, and the seats and handrails are installed directly on the upper cover. Traditional car manufacturers have been emphasizing the use of modular production to reduce production costs, but after all, the parts of traditional fuel vehicles are much more complex than electric vehicles. The simplified three-electricity system structure of electric vehicles provides the possibility for faster production of vehicles, which is exactly what Tesla pursues and where Tesla's profits lie. Mr Musk expects deliveries to easily grow to more than 50 per cent in 2022 and will be fully autopilot this year.

Welcome to subscribe to the WeChat public account "Automotive Industry Focus" to get the first-hand insider information on the automotive industry and talk about things in the automotive circle. Welcome to break the news! WeChat ID autoWechat

Views: 0

*The comments in the above article only represent the author's personal views and do not represent the views and positions of this website. If you have more insights, please feel free to contribute and share.

© 2024 AutoBeta.Net Tiger Media Company. All rights reserved.