In addition to Weibo, there is also WeChat

Please pay attention

WeChat public account

AutoBeta

2024-11-17 Update From: AutoBeta autobeta NAV: AutoBeta > News >

Share

AutoBeta(AutoBeta.net)04/06 Report--

Recently, due to a shortage of semiconductor chips, Mercedes-Benz said it would suspend production at its two factories in Brazil and arrange for more than 5000 workers to take a collective holiday. It is understood that the two factories will stop production from April 18 to May 3, a total of 16 days. Mercedes-Benz said the main reason for the shutdown was the global semiconductor supply crisis and was adjusting the production of auto parts such as trucks, truck cabins and bus chassis.

It is worth noting that Mercedes-Benz arranged paid collective leave for 1200 workers as early as March because of a shortage of semiconductor chips. On March 31st, Mercedes-Benz said that due to the interruption of semiconductor chips caused by the war between Russia and Ukraine, it could only adjust some shifts at the Sindelfingen plant. It is understood that the factory is Mercedes-Benz's largest factory in the mainland, mainly responsible for the production of Mercedes-Benz S-class flagship cars, EQS, and E-class models. A spokesman for Mercedes said the Sindfengen plant continued to operate despite a shortage of parts. It also said Mercedes was reassessing the situation every day and would adopt a "highly flexible approach to avoid shutdowns as much as possible".

In February this year, Mercedes-Benz suspended orders for German E-class models due to lack of core, which made it difficult to meet the growing demand of users. At the end of January, orders for Mercedes-Benz G-Class off-road models were also suspended, and the latest delivery date was extended to the fourth quarter of 2024. Mercedes-Benz has not accepted new orders since January 17, and overseas dealers have rejected several order requests, according to a potential customer from Mercedes-Benz G-Class.

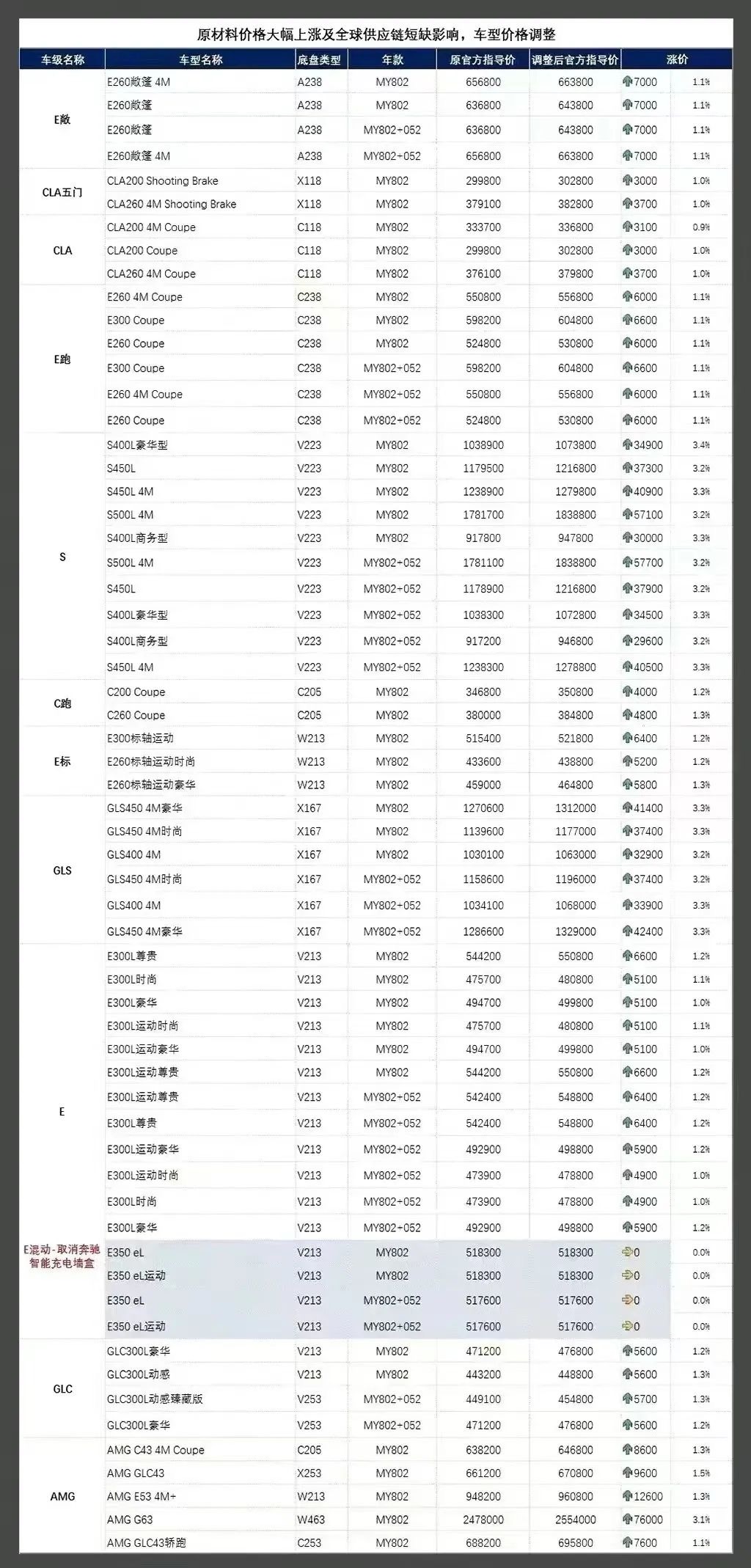

In addition to not accepting new orders, Mercedes-Benz has also adjusted the price of its models. On April 2, a notice sent to dealers by Mercedes-Benz revealed that recently, due to the sharp rise in the prices of some raw materials and shortages in the global supply chain, the recommended retail prices of some models on sale will be adjusted from April 2, 2022. Consumers can consult the local authorized dealer for real-time retail price and more related information, and the final retail price is subject to the contract agreement between the customer and the relevant distributor. As can be seen from the exposed price list, the biggest price increases are Mercedes-Benz S-Class cars and GLS models, with the highest increase of 121000 yuan for vehicles.

In fact, in recent years, due to chip shortage and COVID-19 epidemic and other factors, many overseas factories have announced the suspension of production. In such an environment, vehicle production capacity has also been affected to a certain extent. Take Toyota as an example. Toyota, as the world's largest carmaker, has repeatedly announced a reduction or suspension of production in recent years because of a shortage of chips. A Toyota spokesman has said that Toyota will cut production capacity in Japan's home market by 20% in the three months starting in April, to ease the pressure on suppliers caused by shortages of chips and other parts. Of these, capacity is expected to fall by 20 per cent to 150000 vehicles in April, by about 10 per cent to 100000 in May and by about 5 per cent to 50, 000 in June.

It is not difficult to see that the shortage of automotive chips is the key to the difficulty of automobile production and delivery, and it has also put more pressure on the automobile manufacturing industry. in addition, due to the epidemic and the earthquake in Japan and other factors, the waiting time for semiconductor delivery was extended again in March. According to research agency Susquehanna Financial Group, the current delivery time for semiconductors is 26.6 days.

Welcome to subscribe to the WeChat public account "Automotive Industry Focus" to get the first-hand insider information on the automotive industry and talk about things in the automotive circle. Welcome to break the news! WeChat ID autoWechat

Views: 0

*The comments in the above article only represent the author's personal views and do not represent the views and positions of this website. If you have more insights, please feel free to contribute and share.

© 2024 AutoBeta.Net Tiger Media Company. All rights reserved.