In addition to Weibo, there is also WeChat

Please pay attention

WeChat public account

AutoBeta

2024-11-17 Update From: AutoBeta autobeta NAV: AutoBeta > News >

Share

AutoBeta(AutoBeta.net)04/15 Report--

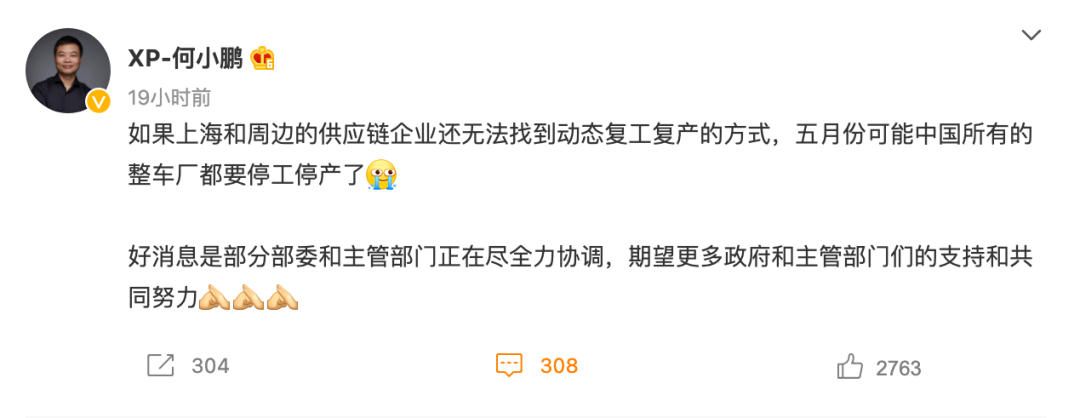

As one of the largest automobile clusters in China, the epidemic in Shanghai continues to ferment and is becoming more and more serious. Just last night, he Xiaopeng sounded the first alarm in 2022: the domestic auto industry may face a total shutdown. He Xiaopeng, founder of Xiaopeng Automobile, wrote on Weibo on the evening of April 14 that "if supply chain companies in and around Shanghai cannot find a way to return to work and production dynamically, all vehicle factories in China may stop production in May." With that, he Xiaopeng did not forget to attach a crying expression.

Netizens have also expressed their views on he Xiaopeng's remarks.

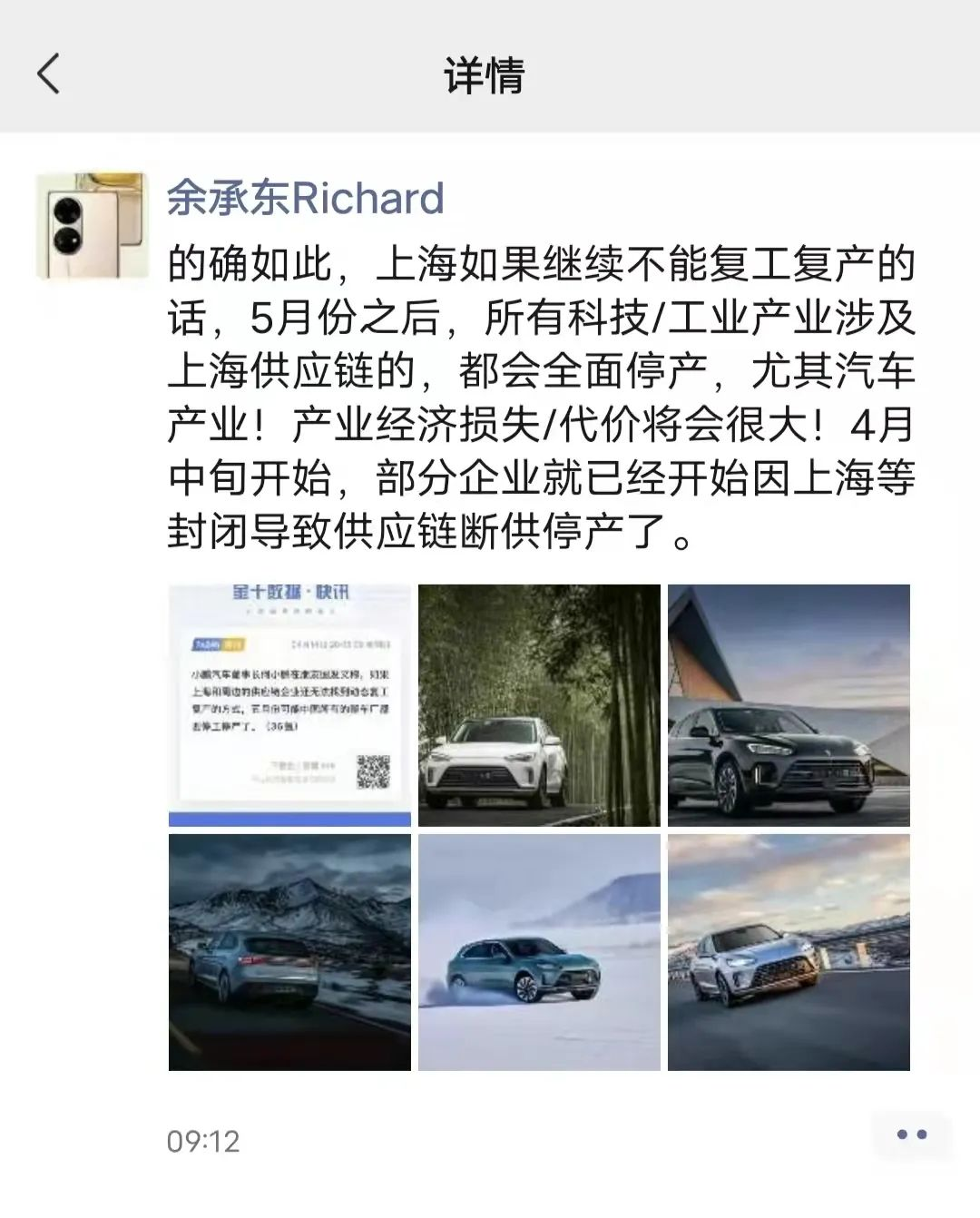

This morning, Yu Chengdong, BU CEO of Huawei, quoted he Xiaopeng as saying: indeed! If we continue to fail to resume work and production, after May, all technology / industrial industries involving the Shanghai supply chain will completely stop production, especially the automobile industry! The economic loss / cost of the industry will be great! Since mid-April, some enterprises have already begun to cut off supply and production in the supply chain due to closures such as Shanghai. "

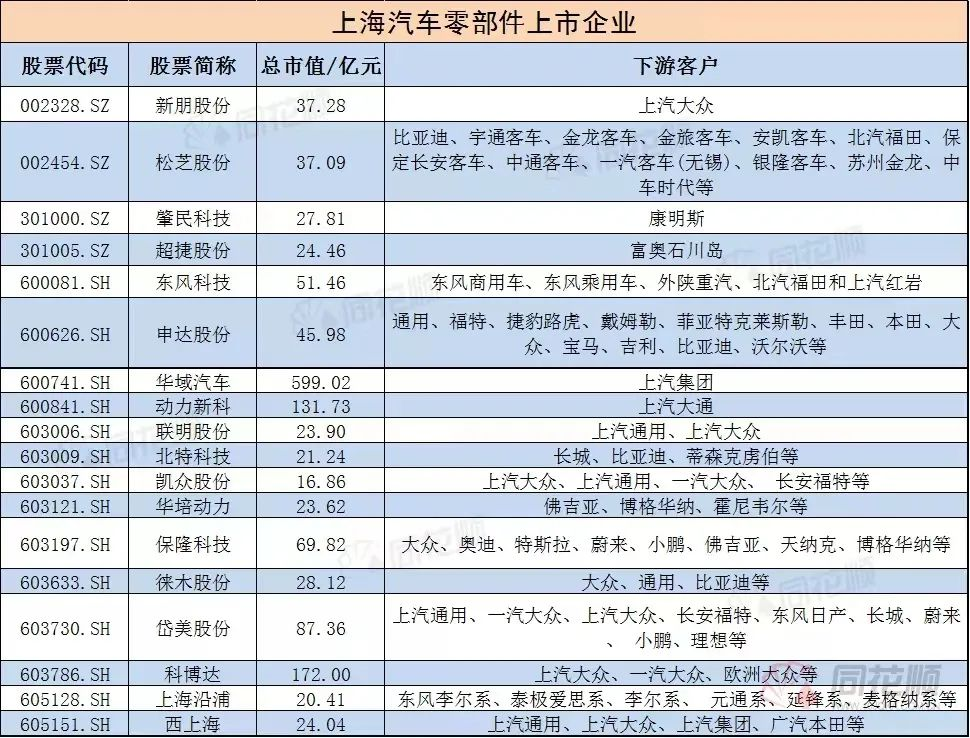

From 0 to 24:00 on April 14, 31 provinces (autonomous regions, municipalities directly under the Central Government) and Xinjiang production and Construction Corps reported 3472 new local cases, including 3200 in Shanghai and 20694 new local asymptomatic infections, including 19872 in Shanghai, according to the National Health Commission. Judging from the data, more than 90% of the new confirmed cases every day come from Shanghai, and the severity of its epidemic prevention and control can be imagined. So, why can the prevention and control of the epidemic in Shanghai directly affect the national automobile industry? The Yangtze River Delta region is the key area of China's automobile industry, with a perfect layout of the automobile industry chain, and Shanghai is also a central city integrating import and export, sales, research and development, its important position is self-evident. Due to the well-developed vehicle manufacturing industry, Shanghai and its surrounding areas also have a quite perfect automobile supply chain system.

In general, in the automobile industry with complex and lengthy supply chain, the automobile industry chain is often built around the leading vehicle enterprises. Jilin and Shanghai are respectively the locations of FAW and SAIC, and their automobile output ranks among the top three in the country. Among them, Shanghai is the core center of China's high-end auto parts enterprises, around the Yangtze River Delta automobile industry supply chain in Shanghai, plays an important role in China's automobile industry. From the perspective of the law of the parts industry, under normal circumstances, large parts will be produced nearby, while some small and sophisticated core parts will be purchased centrally. Bosch, Ambofu and other multinational parts companies produce many important parts in the Yangtze River Delta, so the supply chain impact will spread to car companies in other parts of the country. In addition, the automobile supply chain system is often composed of top-down auto enterprises, primary suppliers, secondary suppliers, tertiary suppliers, etc., one of which is affected, may affect the follow-up supply partners.

For example, Bosch, one of the world's largest car suppliers, has set up its Chinese headquarters in Shanghai and has auto parts production plants in Suzhou and Wuxi. At the same time, companies such as NXP and Qualcomm, the main automotive electronic components suppliers, have also set up R & D, sales and other departments in Shanghai. Besides Bosch, Ambofo, the largest wire harness supplier in China, has several production bases in Jiading District, Shanghai. It is an important wire harness supplier for vehicle manufacturers such as Tesla, SAIC General Motors, SAIC Volkswagen, FAW, FAW, Chery, Great Wall, while other wire harness suppliers Kunshan Huguang, Suzhou Portney and Shanghai Jinting all have factories in Shanghai. In other words, the current epidemic in Shanghai is in a severe period, and the shutdown of parts suppliers will directly hinder the production of automakers, which is also the direct reason why he Xiaopeng and Yu Chengdong respectively sounded the danger alarm in the supply chain.

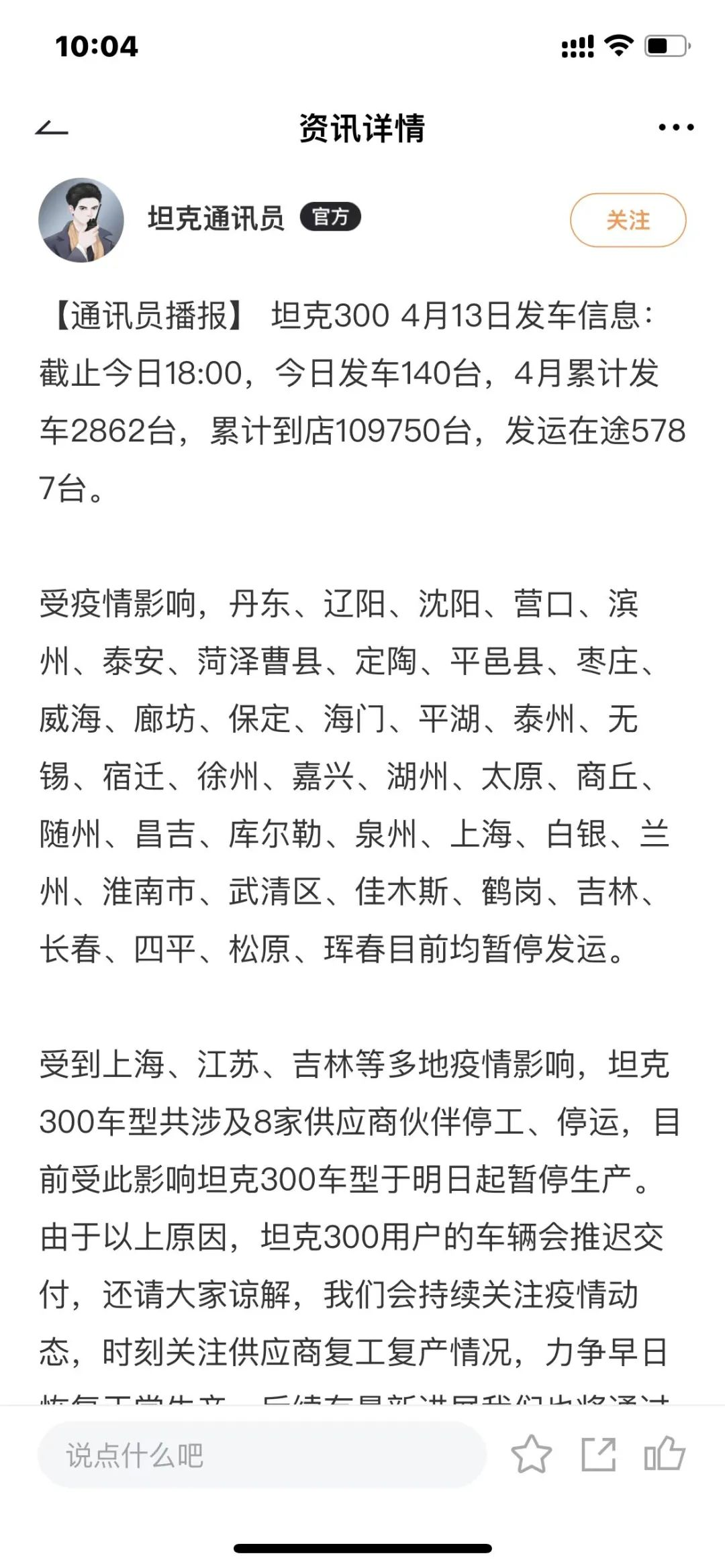

As an automobile industry with long industrial chain and strong cooperation, the continuous epidemic has indeed had a certain impact on automobile production. According to statistics, since March this year, a number of mainframe factories, including BMW, FAW and Tesla, have stopped production due to the epidemic. On April 9, NIO issued a statement saying that production of the whole vehicle was suspended because of the epidemic affecting the supply chain. On April 14, the tank brand officer of Great Wall announced that due to the impact of the epidemic in many places, the tank 300 models involved eight supplier partners to stop work and operation. At present, the production of tank 300 models has been suspended since April 14.

According to relevant documents, SAIC is promoting the resumption of work and production, and plans to give feedback on the return to work on April 17 and launch the stress test on April 18. For returning employees, nucleic acid is required to be tested every 48 hours. In response to the above rumors, SAIC said, "SAIC has set a target for resuming work and production within SAIC, but there may be adjustments according to the control of the epidemic and its own preparations." At present, we should first cooperate with epidemic prevention in accordance with the requirements of the government, maintain and transform equipment at the same time, and carefully make relevant preparations for production to meet the conditions of epidemic prevention. " In addition, SAIC GM Wuling said: "at present, the company is flexible through the flexible adjustment of various bases, production lines and product varieties, so as to minimize the negative impact of the epidemic."

In response to the voices of he Xiaopeng and Yu Chengdong, Cui Dongshu, secretary general of the Federation of passengers, said, "it should not go so far (completely stop production). Let's see how to save ourselves." Cui Dongshu said that the epidemic in Shanghai and other places is expected to bring 20% of the production loss to the domestic auto industry. At the same time, the "Jiangsu and Zhejiang emblem" zone with Shanghai as the core is also the core area for the supply of core automotive parts, and the epidemic in Shanghai will have a great impact on the supply of key parts of the automobile industry.

On April 11, the equipment Industry Development Center of the Ministry of Industry and Information Technology issued a notice on the launch of the 'Automotive Industry chain supply chain unimpeded Coordination platform'. According to the notice, in order to further ensure the smooth flow of the automobile industry chain supply chain, entrusted by the first equipment Industry Department of the Ministry of Industry and Information Technology, our center officially launched the "Automotive Industry chain supply chain unimpeded Coordination platform" on April 11, 2022 to help automobile industry chain supply chain enterprises feedback and solve practical problems in a timely manner.

It should be noted that the recurrence of the epidemic still makes the task of steady growth of domestic automobile production and sales become arduous. The China Automobile Association said that looking forward to the situation for the whole year, the development of the automobile industry is facing triple pressure of demand contraction, supply shock and expected weakening due to macroeconomic impact. Local governments should refine the national policies and measures to stabilize growth as soon as possible, and enterprises should continue to take effective measures, and suggest that government departments introduce policies and measures to promote automobile consumption, including the previous effective policy of halving purchase tax.

After experiencing a shortage of chips since 2021, China's auto industry faces another challenge: the impact of spare parts production in the Yangtze River and Pearl River Delta region. For the Chinese market, under the influence of the epidemic and the supply of spare parts, car production reduction will become the norm, but the impact of the Shanghai epidemic on the domestic automobile market is unprecedented. As for how much damage the epidemic will eventually bring to the entire auto industry, it will depend on how long it will take for the company to resume normal operation. Of course, we should also be full of confidence in our country. China has sufficient experience in epidemic prevention, and it is easier to implement it in various places, and after this incident, the layout of China's automobile industry will also be more perfect.

Welcome to subscribe to the WeChat public account "Automotive Industry Focus" to get the first-hand insider information on the automotive industry and talk about things in the automotive circle. Welcome to break the news! WeChat ID autoWechat

Views: 0

*The comments in the above article only represent the author's personal views and do not represent the views and positions of this website. If you have more insights, please feel free to contribute and share.

© 2024 AutoBeta.Net Tiger Media Company. All rights reserved.