In addition to Weibo, there is also WeChat

Please pay attention

WeChat public account

AutoBeta

2024-11-21 Update From: AutoBeta autobeta NAV: AutoBeta > News >

Share

AutoBeta(AutoBeta.net)05/28 Report--

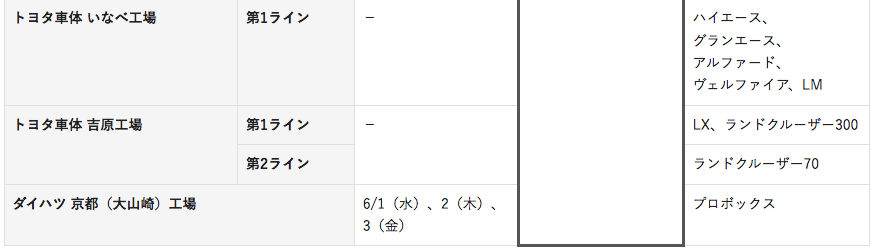

In the face of the coming June, Toyota issued two notices to stop production and cut production in a week. Toyota announced on its website on May 27th that Toyota would suspend operations at some of its local factories on June 6. as a result, Toyota lost production of another 50, 000 vehicles, falling to 800000 in June. Among them, production in the Japanese market is planned to be about 200000 and that in overseas markets is planned to be 600000.

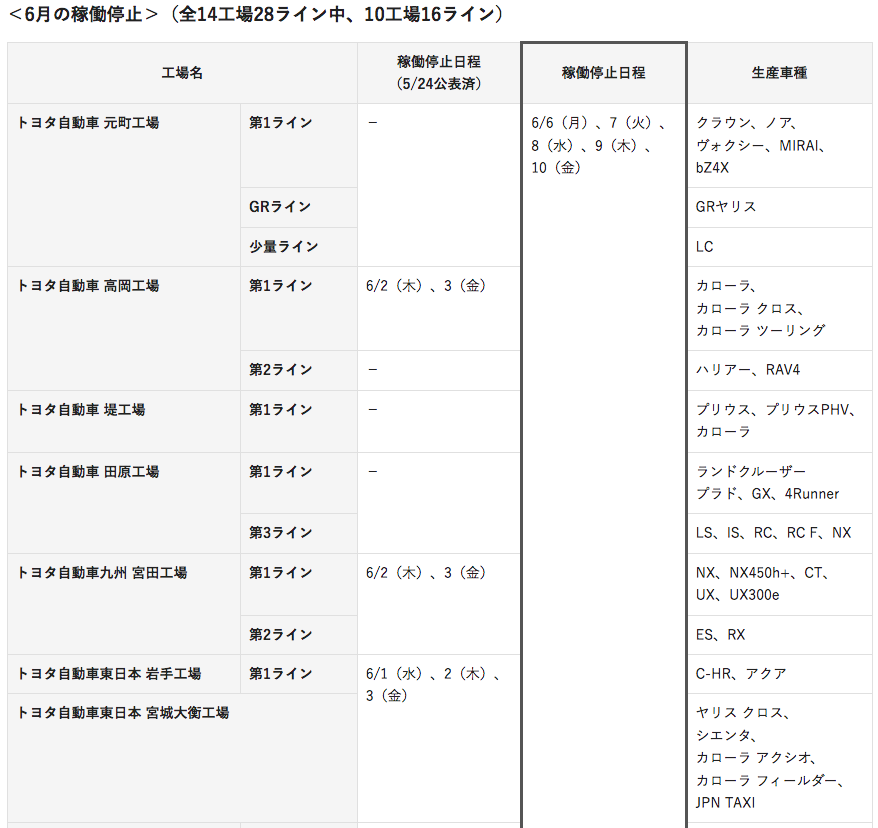

This is the second time Toyota has announced a shutdown and production cuts since May 24. On May 24, Toyota announced that operations at some local factories in Japan would be suspended in May and June. Toyota pointed out that out of a total of 28 production lines in 14 factories in Japan, 16 production lines in 10 factories would be suspended from the end of this month (from May 25) to the beginning of June (as of June 3). In view of this, the maximum shutdown time is 5 days, and the rest of the factories will stop production for about 3 days. Toyota cut its June production target by 100000 to 850000.

According to Toyota, both plant shutdowns and production cuts were caused by parts shortages caused by the spread of the epidemic, and the announcement of the shutdown twice in a week also directly led to a decline in Toyota's production capacity in June. Toyota's production capacity fell by 150000 vehicles in June compared with the expected production of about 950000 in June, which means that Toyota's production plan will become more difficult in the second half of the year. On May 24th, Toyota stressed that the global average monthly production from June to August this year was about 850000 vehicles, that is, Toyota produced a total of about 2.55 million vehicles from June to August this year, and the production target for fiscal year 2022 (April 2022 to March 2023) remained unchanged at about 9.7 million vehicles previously announced. In the latest notice, Toyota still stresses that the global average monthly production is about 850000 vehicles from June to August this year, and is expected to produce about 9.7 million vehicles in fiscal year 2022. However, Toyota also pointed out that due to the continued closure in Shanghai and the unpredictable supply of spare parts, future production plans may be reduced, but will do its best to curb sudden production cuts.

The auto industry has learned from Toyota's official website that Toyota has faced production stoppage and production cuts almost every month since March this year, mostly due to disruptions in the supply of spare parts caused by the epidemic. The automobile industry is originally an industry with a very long industrial chain. The manufacturing and production of a car involves tens of thousands of parts. The lack of any one of the parts will lead to the failure of the whole vehicle to leave the factory, which is limited by the interruption of parts supply. Toyota Motor may be forced to change its production target many times.

In fiscal year 2021 (April 2021-March 2022), Japanese car companies did not perform well due to the continued impact of the epidemic, parts supply shortages and rising logistics prices of raw materials. Toyota's global sales of 10.38 million vehicles, of which Japan's domestic market production and sales data showed a "double decline". Specifically, its production was 2.76 million, down 5.4% from a year earlier, the lowest in nearly 45 years since 1976 (2.58 million). Sales were 1.39 million, down 9.3% from a year earlier, the lowest for the second year in a row. In addition, among Japan's eight major car companies, Mazda fell 16%, the highest decline among Japan's eight car companies.

Prior to this, the National Federation of Light Automobile Associations of Japan publicly said that in addition to the shortage of semiconductors, the epidemic in Southeast Asia led to a stagnation in the procurement of parts and components, and manufacturers' factories had to stop or reduce production, affecting the sales of new cars. Previously, car companies including Honda, Mazda, Mitsubishi and Subaru all faced production suspension or production cuts. In addition, although the problem of chip shortage this year has been alleviated to some extent, it has not been completely solved so far. On May 27, Nippon Steel, Japan's largest steelmaker, said that due to the soaring price of raw materials, the production cost per ton of steel is expected to increase by 40,000 yen ($314) per ton by the end of September this year compared with the end of the first quarter. This also includes an increase in fuel and logistics costs. Toyota has previously pointed out that the rise in raw materials will have a negative impact on results in the current fiscal year, and operating profit is expected to decline in the current fiscal year.

Judging from the current situation of Japanese car companies, due to the epidemic, supply chain disruptions and rising raw material prices, the sales of some Japanese car companies are still not optimistic since the beginning of fiscal year 2022. Take the latest domestic data as an example, Toyota sold 111100 vehicles in China in April, down 30.7% from a year earlier; Nissan sold 69300 vehicles in China, down 46% from a year earlier; and Honda sold 95200 vehicles in China, down 36.3% from a year earlier.

Welcome to subscribe to the WeChat public account "Automotive Industry Focus" to get the first-hand insider information on the automotive industry and talk about things in the automotive circle. Welcome to break the news! WeChat ID autoWechat

Views: 0

*The comments in the above article only represent the author's personal views and do not represent the views and positions of this website. If you have more insights, please feel free to contribute and share.

© 2024 AutoBeta.Net Tiger Media Company. All rights reserved.