In addition to Weibo, there is also WeChat

Please pay attention

WeChat public account

AutoBeta

2024-11-18 Update From: AutoBeta autobeta NAV: AutoBeta > News >

Share

AutoBeta(AutoBeta.net)06/23 Report--

Tesla plans to suspend most production at his Shanghai plant in the first two weeks of July because of upgrades, Reuters and other media reported on June 22nd. After the upgrade is completed, Tesla plans to bring the plant's production capacity to a new record by the end of July, close to the target of 22000 vehicles a week. Tesla initially planned to increase the weekly production capacity of the Shanghai plant to 8000 Model3 and 14000 Model Y vehicles by mid-May, but the plan was delayed because of the epidemic, according to people familiar with the matter.

In response to the above report, Tesla, a relevant official in China, said: "there is no such news."

According to automotive industry inquiries, Tesla Shanghai factory is located in Shanghai Lingang New District, covering an area of 860000 square meters, including vehicle production area, test area, parts production area and joint plant (maintenance workshop). The factory mainly produces Model 3 and SUV Model Y cars, which is by far the largest foreign manufacturing project in Shanghai, and Tesla's second overseas super factory. The operation of the factory is very important to Tesla.

Tesla officially entered the Chinese market in December 2018 and signed a pure electric vehicle project investment agreement with the Shanghai Municipal Government and Shanghai Port Management Commission in July 2018. Tesla Shanghai Super Factory entered pilot production in November 2019, and Model 3 manufactured in Shanghai factory began delivery in January 2020. By March 2020, in order to localize the supply chain, Tesla invested $2 billion in a component plant in China and plans to expand factory capacity. In the past new car delivery data, the data show that Tesla's global production in 2020 was 509000 vehicles, an increase of 144000 over the previous year, of which the Shanghai Super Factory produced 144000 vehicles for the whole year, that is to say, all the increased capacity of Tesla that year came from the Shanghai Super Factory. In this year, Tesla made an annual profit for the first time since its establishment, with a net profit of 862 million US dollars. In 2021, Tesla relies on the Shanghai factory to deliver 484000 new cars for the whole year, an increase of 235% over the same period last year, accounting for 51.7% of Tesla's total global delivery volume, making it Tesla's first single market in the world. Of these, 321000 are sold domestically, and the remaining 163000 are mainly exported to Japan, Europe and other countries. In the Chinese market, there are 169853 Model Y retail vehicles and 150890 Model 3 retail vehicles in 2021. In response to the new car delivery performance in 2021, Tao Lin, global vice president of Tesla, said in an online speech at the opening ceremony of the third Qingdao Summit of multinational leaders: "the Shanghai Super Factory is continuing to become Tesla's most important export base and production center. In 2021, the Shanghai factory delivered more than 480000 pure electric vehicles to global users, accounting for half of Tesla's global delivery volume. And send high-level made in China to the world. " Tesla CEO Musk also said last month that the Chinese market would account for 25-30 per cent of Tesla's sales in the long run. From here, we can also directly see the importance of Tesla's Shanghai factory to Tesla.

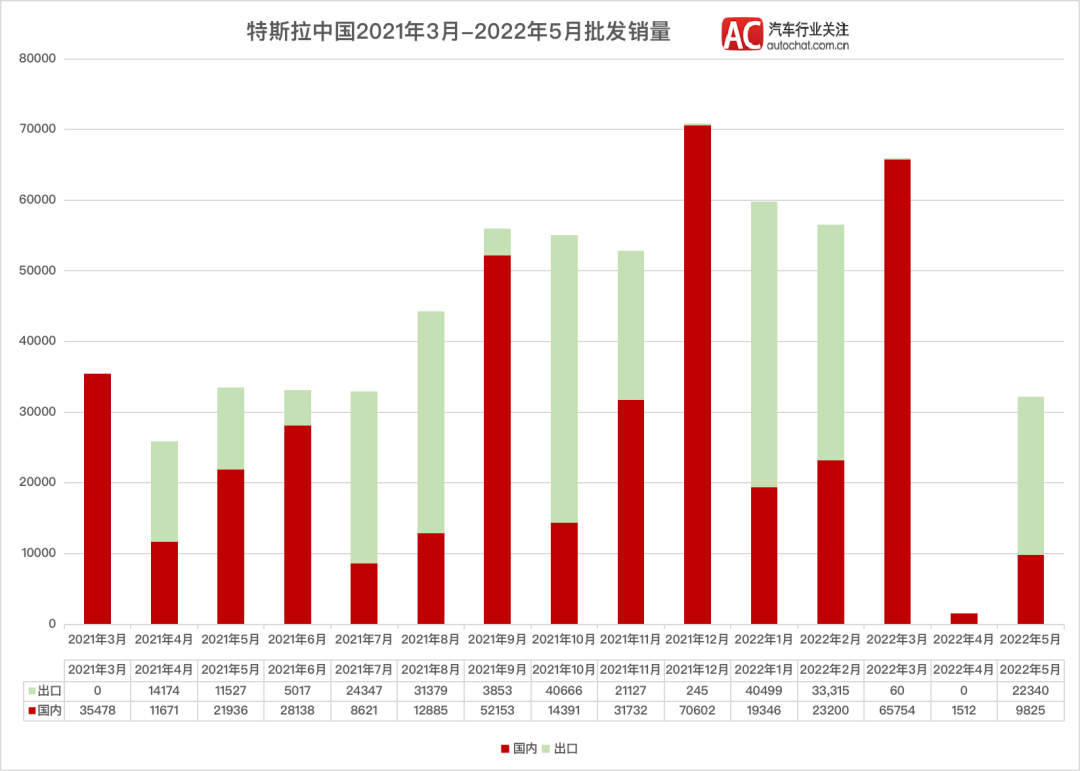

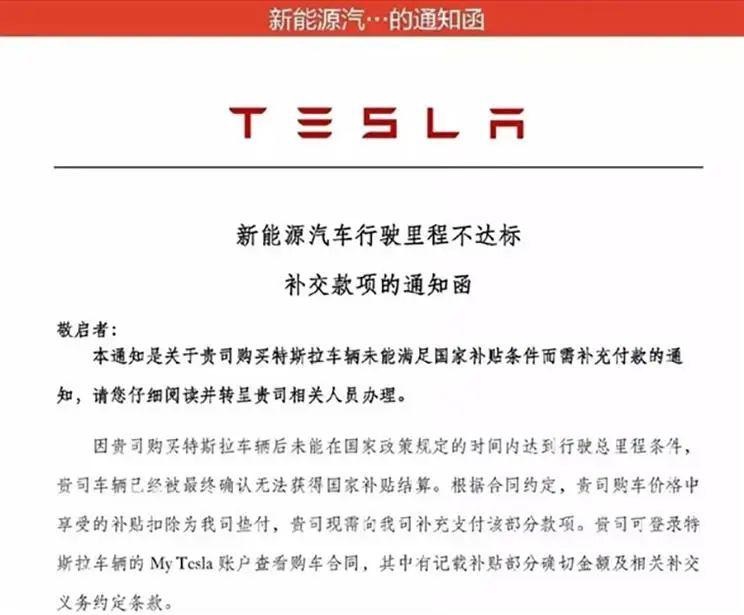

As for this year's delivery target for the new car year, according to Tesla CEO Musk's previously announced plan, Tesla's delivery target this year is to increase by 50%, that is, based on the total sales of 936000 in 2021, Tesla needs to deliver 1.4 million new cars this year. According to relevant data, from January to May this year, Tesla delivered a total of 215851 new cars in China, an increase of more than 50 per cent over the same period last year. Among them, in the first quarter, Tesla delivered 310048 vehicles worldwide, and Tesla Shanghai factory delivered 182174 vehicles, accounting for 58.76% of Tesla's total global market share, becoming Tesla's global single market. However, in April and May, due to the influence of the epidemic and the implementation of epidemic control measures in Shanghai, Tesla's Shanghai factory began to stop production at the end of March this year and did not resume work until April 19. the cumulative shutdown time is as long as 22 days (Tesla's production loss may exceed 40, 000 vehicles based on an average daily production capacity of 2000 vehicles), which has affected Tesla's production and sales in April and May. Among them, the output of the Shanghai factory in April was only 10757 vehicles, a month-on-month decline of more than 80%. The delivery volume was only 1512. Fortunately, the epidemic improved in May, and its production and sales improved compared with April. Tesla's wholesale sales in China in May were 32165, including 22340 for export and 9825 for domestic retail. In response, Tesla CEO Elon Musk (Elon Musk) said at the Qatar Economic Forum (Qatar Economic Forum) on June 21, "our constraints are more in terms of raw materials and expanding production, and we are increasing production as soon as possible." Affected by the spread of COVID-19 's epidemic, the output of Tesla's Shanghai factory is expected to drop by more than 1/3 in the second quarter compared with the first quarter.

Of course, as mentioned above, the decline in capacity in Tesla China in April and May was more affected by the epidemic. Tesla is reported to have reached full capacity so far, and the Shanghai plant has produced 17000 Model 3 and Model Y cars a week since mid-June. However, the automobile industry is concerned that although production at Tesla's Shanghai factory has resumed, Tesla still needs to go through a long climb to return to the pre-epidemic level, and the current production speed is still relatively slow, and there may be a certain lag in production. According to Tesla's official website, the longest delivery cycle of domestic models Model 3 and Model Y is 24 weeks (5.5 months), and the expected delivery time of domestic Model 3 is 16-20 weeks (about 3.7-4.6 months). The delivery time of domestic Model Y is expected to be 10-14 weeks (about 2.3-3.2 months), that is, even if the domestic model is ordered now, it will take 2 to 3 months to mention the new car at the earliest. In addition, Australian Model Y consumers will not complete delivery until the first quarter of 2023, while European consumers will have to wait until the fourth quarter of this year.

Welcome to subscribe to the WeChat public account "Automotive Industry Focus" to get the first-hand insider information on the automotive industry and talk about things in the automotive circle. Welcome to break the news! WeChat ID autoWechat

Views: 0

*The comments in the above article only represent the author's personal views and do not represent the views and positions of this website. If you have more insights, please feel free to contribute and share.

© 2024 AutoBeta.Net Tiger Media Company. All rights reserved.