In addition to Weibo, there is also WeChat

Please pay attention

WeChat public account

AutoBeta

2024-11-22 Update From: AutoBeta autobeta NAV: AutoBeta > News >

Share

AutoBeta(AutoBeta.net)06/23 Report--

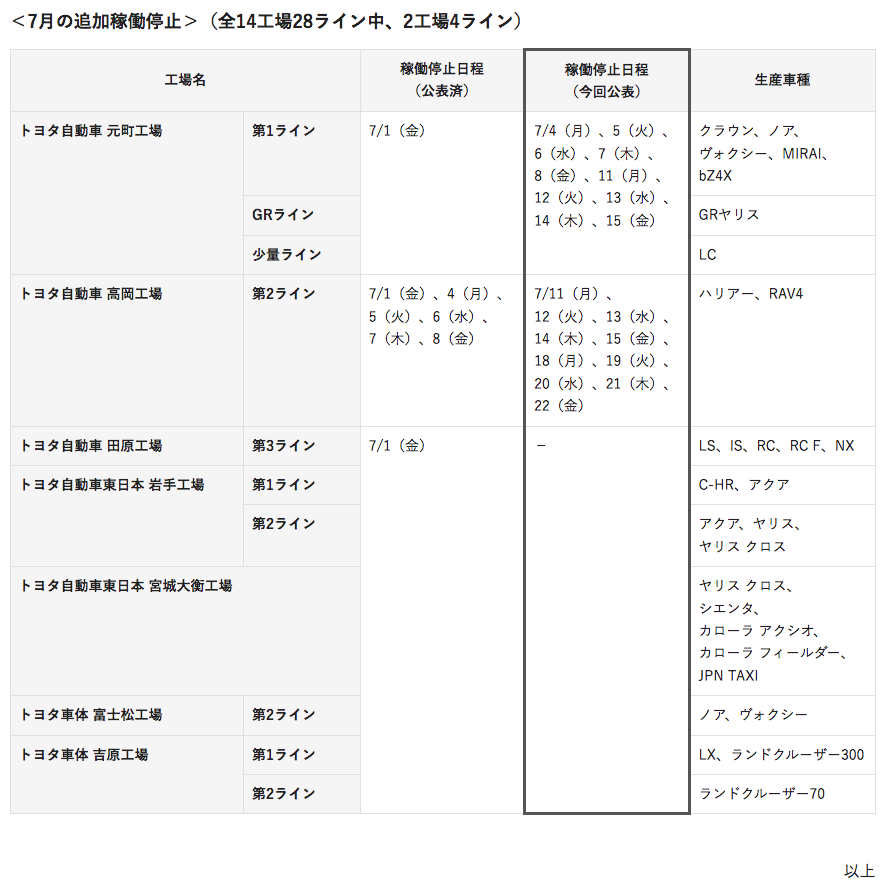

On June 22nd, Toyota announced its global production target for July. According to Toyota's official website, Toyota's global production target in July was reduced to 800000 vehicles (of which, about 250000 vehicles were produced locally in Japan and about 550000 vehicles were produced overseas). The reduction is 50, 000 vehicles less than the previous forecast of 850000 vehicles, which is due to the outbreak of the COVID-19 epidemic in a Toyota supplier. However, there are only two factories with a total of four production lines, namely, the Wonmachi plant and the Takaoka plant in Toyota City, Aichi Prefecture. The two plants will stop production to varying degrees from July 4 to July 22, for a total of 10 days, including Toyota Crown and RAV4.

Not long ago, Toyota announced that its global production target for June this year would be cut again to 750000 vehicles, including the Wonmachi plant, where some production lines have been suspended since June 17. Coupled with the shutdown time, the plant will stop production for more than half a month.

According to past reports on the industry's official website, Toyota has faced production cuts almost every month since March, mostly due to disruptions in semiconductor and raw material shortages caused by the epidemic. Although Toyota has repeatedly cut its monthly pre-production plan, Toyota still stresses that its full-year production plan for fiscal year 2022 (April 2022-March 2023) remains unchanged at about 9.7 million vehicles previously announced. According to Toyota officials, Toyota's global production is expected to be about 850000 vehicles a month from July to September, and it has been cut to 800000 vehicles in July, meaning Toyota's production capacity may be under greater pressure.

Of course, Toyota is not the only Japanese car company facing production cuts. Since the beginning of this year, including Honda, Mazda, Mitsubishi, Subaru, Nissan and other car companies are facing the problem of stopping or reducing production, and the negative impact of capacity decline is also reflected in the sales side. Public data show that among the eight major Japanese brands, except Mitsubishi, Toyota, Honda, Nissan, Suzuki, Subaru, Mazda and Daihatsu all showed a year-on-year decline in sales. Toyota's sales fell 20.9% year-on-year to 86500; Suzuki sales fell 10.9% to 6741; Subaru sales fell 27.5% to 3480 Mazda sales fell 49.3 per cent year-on-year to 3332 vehicles; Lexus sales fell 30.8 per cent to 3103 vehicles; and Dafa car sales fell 30.1 per cent to 1812 vehicles. There is also a clear downward trend in the domestic market. Toyota's sales in China fell 12.1% to 148500 vehicles in May from a year earlier; Honda's sales in China fell 30.8% to 89000 vehicles; Nissan's sales in China fell 38.0% to 68800 vehicles; and Mazda's sales in China fell 43.8% to 8300 vehicles.

As for the reasons for the decline in sales, multi-car companies said it was mainly due to logistics disruptions, difficulties in purchasing spare parts and stagnation of factory production lines caused by a shortage of semiconductors, previous restrictions in Shanghai, geopolitics in Russia and Ukraine. The Japanese Federation of Automobile sales Associations and the National Federation of Mini-vehicle Associations said: "the shortage of semiconductors and the previous difficulties in purchasing parts in Shanghai due to epidemic control have led to the stagnation of production by Japanese automakers, which has had an impact on new car sales. At present, Shanghai has fully resumed work and production on June 1, but some factories will still suspend production in June, which may have a lasting impact on new car sales in Japan. Although the shortage of parts and components will probably gradually ease, the situation is complicated and it is still difficult to predict the future. In other words, affected by the supply chain, the production capacity of Japanese car enterprises is still limited, and the capacity constraints have also had an impact on the relevant auto parts manufacturers, and the depressed state of new car sales of Japanese car companies has not been improved.

Welcome to subscribe to the WeChat public account "Automotive Industry Focus" to get the first-hand insider information on the automotive industry and talk about things in the automotive circle. Welcome to break the news! WeChat ID autoWechat

Views: 0

*The comments in the above article only represent the author's personal views and do not represent the views and positions of this website. If you have more insights, please feel free to contribute and share.

© 2024 AutoBeta.Net Tiger Media Company. All rights reserved.