In addition to Weibo, there is also WeChat

Please pay attention

WeChat public account

AutoBeta

2024-11-18 Update From: AutoBeta autobeta NAV: AutoBeta > News >

Share

AutoBeta(AutoBeta.net)07/29 Report--

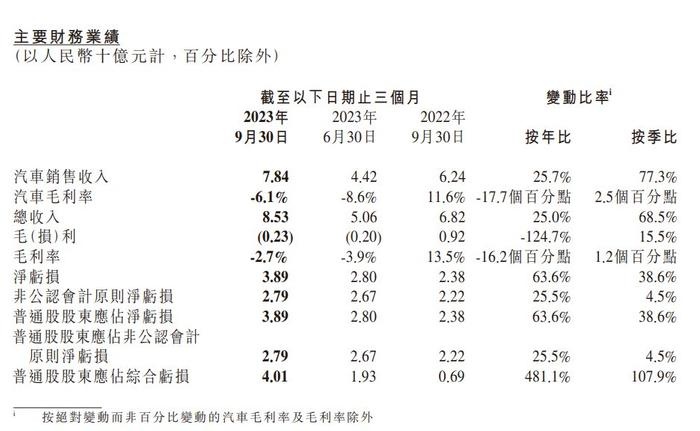

According to the latest report of Japan's Kyodo News Agency, Toyota and other eight major Japanese car companies have released production and sales figures for the first half of this year. According to the data, the total global sales of eight car companies fell 11.4% year on year to 11.63 million vehicles in the first half of the year, and five of them declined compared with the same period last year. Specifically, Toyota's global sales fell 6.1% to 4.69 million vehicles in the first half of the year, the first year-on-year decline in two years; Honda fell 19.5% year-on-year to 1.9 million vehicles; Nissan fell 23.9% to 1.67 million vehicles; Mazda dropped 22.0% Subaru fell 19.3 per cent from a year earlier; Suzuki rose 2.0 per cent year-on-year to 1.46 million vehicles; Mitsubishi Motors rose 0.9 per cent from a year earlier.

In terms of production, the total global production of eight Japanese passenger car manufacturers, including Toyota, Suzuki, Honda, Nissan, Subaru, Mitsubishi and Mazda, fell 6 per cent year-on-year to 11.55 million vehicles in the first half of this year, lower than the previous year for the first time in two years. Six of them fell year-on-year, including Toyota 3.4%, Honda 10.2%, Nissan 14.4%, Mazda 18.3%, only Suzuki and Subaru grew.

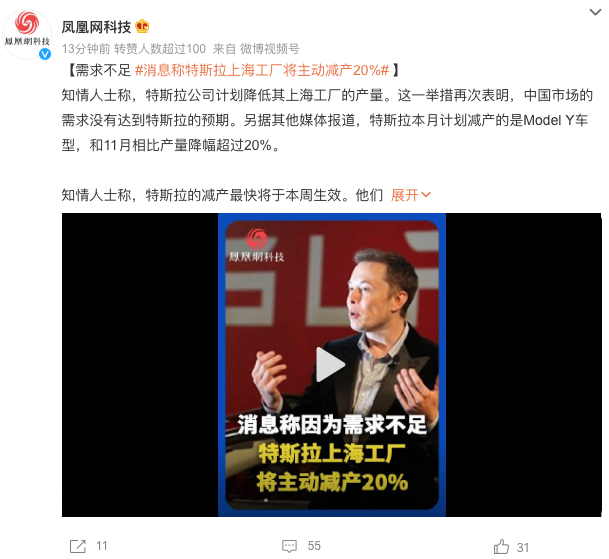

The automobile industry is concerned that the decline in production and sales data of the above-mentioned car companies in the first half of the year is mainly due to the shortage of spare parts, epidemic control policy, Russia-Ukraine geopolitics and other uncertain factors, affected by this, the Japanese camp, including Toyota, Honda, Nissan, Mazda and other auto companies have been a greater impact on production and sales. Take Toyota as an example, after entering 2022, Toyota faces the problem of shutdown and production reduction almost every month, and most of the reasons for the shutdown are related to parts shortage, closure policy and so on. In mid-June, Toyota announced three factory shutdowns and was forced to cut production, reducing production capacity from the original 950000 to 750000 vehicles, with a cumulative reduction of about 200000 vehicles. The suspension or reduction of production has directly restricted the sales of new cars in the global market of car companies.

According to statistics, in the first half of this year, the production of eight Japanese car companies in the Japanese local market fell 14.3% to 3.42 million vehicles compared with the same period last year, and new car sales (including light vehicles) fell 15% year on year to about 2.0862 million vehicles, the lowest level since the first half of 2011 (about 1.919 million vehicles). Among them, Toyota (excluding Lexus) sold about 638000 vehicles in Japan, down 19% from the same period last year. Subaru sold about 46000 vehicles in Japan, down 21% from a year earlier.

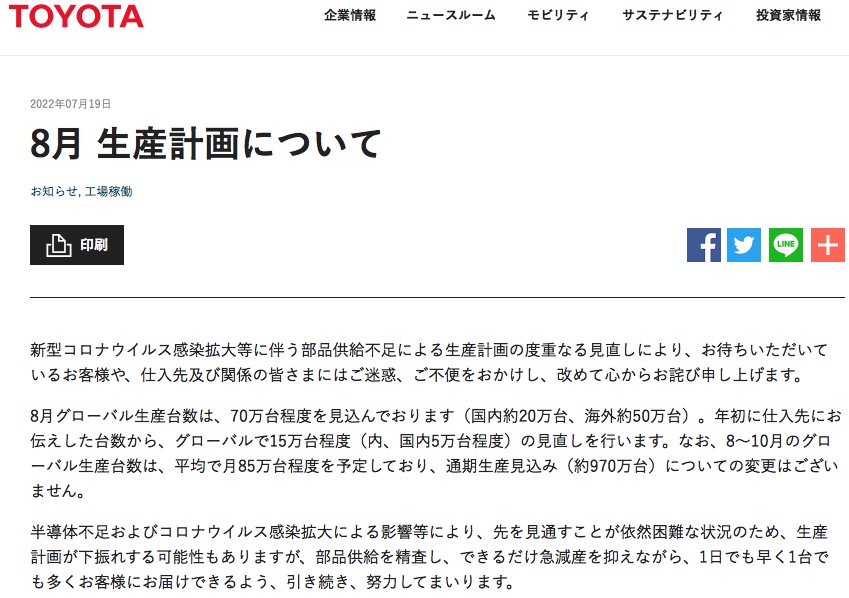

After entering July, Japanese car companies are still deeply affected by the epidemic and supply chain, and the capacity constraints of car companies continue. Toyota announced on its website that it has a global production target of about 700000 vehicles in August, including about 200000 in Japan's domestic market and 500000 in overseas markets. Affected by COVID-19 's epidemic situation, parts supply shortage and the annual normal summer break, Toyota Motor has a total of 14 factories in Japan with 28 production lines. A total of 6 factories, including Woncho factory (Toyota City, Aichi Prefecture), Takei Factory (Toyota City, Aichi Prefecture), and car body Yoshihara Factory (Toyota City, Aichi Prefecture), will suspend the operation of some factory production lines during August. The affected models include bZ4X, RAV4, RAV4 PHV, Camry and Lexus LX. Among them, the longest shutdown time is the Wonmachi factory in Toyota City, Aichi Prefecture, where part of the production line will be suspended for 18 days in August; the shortest shutdown time is at the Toyota body Yoshihara plant and Toyota Industries, which stopped production for one day on August 1 and August 22, respectively, with a normal annual summer break from Saturday, August 13 to Sunday, August 21.

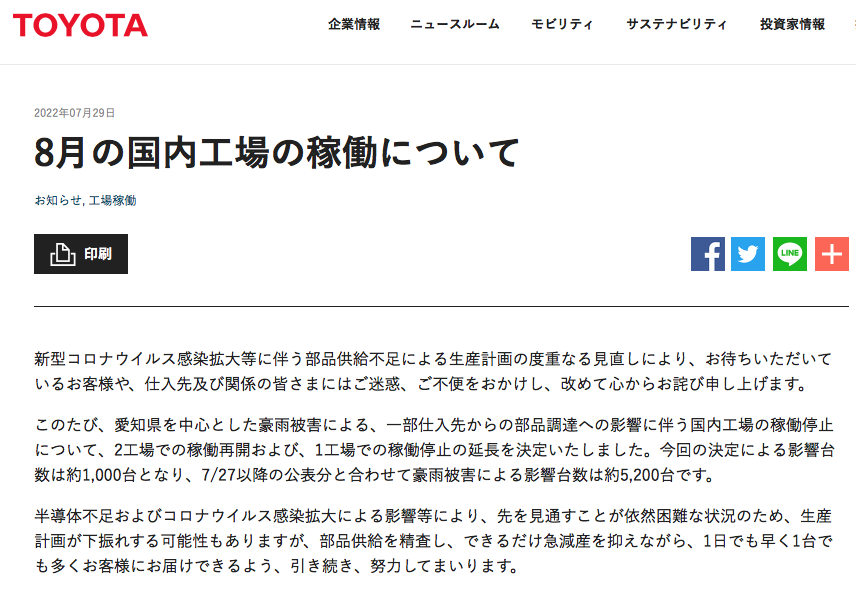

On July 27th, Toyota announced that due to the outbreak of COVID-19, a production line at Toyota's Takaoka plant suspended night shift operation, resulting in a loss of production of about 650 vehicles. On July 28, Toyota announced that it would suspend more production lines in Toyota's home market due to heavy rain. Toyota said that it was difficult to purchase auto parts in Aichi Prefecture and other places in central Japan. To this end, production was suspended in 2 of 28 production lines in 14 factories in Japan's local market. As a result, Toyota cut domestic production by about 4000 vehicles in July. Toyota said on July 29th that two factories affected by the torrential rain had resumed normal operations, while two production lines at another plant had extended the shutdown time, affecting about 1000 vehicles and a cumulative total of about 5200 vehicles affected by the torrential rain. Toyota stressed that due to many uncertainties, production in the coming months is still difficult to predict, but will strive to deliver as many products as possible to customers as soon as possible.

In addition to this situation in Toyota, the production problems of a number of Japanese car companies are also in a serious state, also because the spread of COVID-19 's epidemic disrupted the supply chain of some auto parts and was eventually forced to stop production or cut production. Honda announced on its website on July 21 that as a result of these factors, the Suzuki plant in western Japan will suspend production on two production lines and cut production by about 10% in July, and production at the plant in early August will be about 30% lower than previously planned. The plant in Saitama prefecture north of Tokyo will also cut production by about 10% early next month.

According to AFS statistics, as of July 24, due to chip shortage and other factors, the global automobile market has reduced production by about 2.7873 million vehicles this year. AFS predicts that global carmakers will cut 3.65 million vehicles by the end of the year due to lack of cores. Judging from the current trend, Japanese car companies are still experiencing a shortage of semiconductors and raw materials, and the state of depressed production capacity and sales has not been completely improved.

Welcome to subscribe to the WeChat public account "Automotive Industry Focus" to get the first-hand insider information on the automotive industry and talk about things in the automotive circle. Welcome to break the news! WeChat ID autoWechat

Views: 0

*The comments in the above article only represent the author's personal views and do not represent the views and positions of this website. If you have more insights, please feel free to contribute and share.

© 2024 AutoBeta.Net Tiger Media Company. All rights reserved.