In addition to Weibo, there is also WeChat

Please pay attention

WeChat public account

AutoBeta

2024-11-17 Update From: AutoBeta autobeta NAV: AutoBeta > News >

Share

AutoBeta(AutoBeta.net)09/18 Report--

Since 2020, the delay of new car delivery and the forced interruption of production due to the epidemic and the interruption of the chip supply chain has become an old topic in the automobile industry. After entering 2022, although the "core shortage" has been alleviated, it still continues and affects the global automobile production of some auto companies. Automaker Stellantis and France's Renault will suspend production at some Spanish plants in the coming days and weeks because of chip shortages, Reuters reported. It is reported that two Renault plants in the Castilla and Leon regions of Spain will temporarily suspend production, one of which will be completely closed on September 17, and the other will cancel shifts this week and next week; while Stellantis's plant in Vigo, northwest Spain, has cancelled the night shift from 17 to 18 September.

It should be noted that before this, the two car companies have experienced a number of factory shutdowns. Stellantis, the carmaker, told the media on Aug. 25 that its plant in Sochaux, France, had suspended production until Aug. 26, which was also due to a shortage of semiconductors. Apart from the Socho plant, Stellantis also suspended five production shifts at its Opel car plant in Zaragoza, northern Spain, for the same reason. Not long ago, Volkswagen and Stellantis plants in Zaragoza, Spain, also announced that they would stop production because of a shortage of auto parts. Earlier in February, several European and American car companies, including German Volkswagen, French carmaker Renault and tyre maker Nogi Tire, announced plans to stop production or transfer product lines at some factories because of parts shortages and geographical conditions.

In fact, the chip shortage has had a serious impact on carmakers around the world. In addition to the above-mentioned factories, Honda announced on its website on Aug. 25 that it was affected by a shortage of components such as semiconductors, the spread of COVID-19 and stagnant logistics. Honda is also facing production cuts again. Honda said two production lines at the Suzuki plant in western Japan would cut production by about 30 per cent in early September, while the Saitama plant north of Tokyo would also cut production by about 40 per cent in early September. Affected by this, Honda's production of a number of models, including Feido, Civic, Vezel SUV, Stepwgn minivan and so on, has been affected to varying degrees. Honda also said that due to the epidemic and semiconductor shortages caused by parts reception and logistics delays, Suzuki and Saitama prefecture plants will reduce production by about 30% and 10% respectively for the rest of this month.

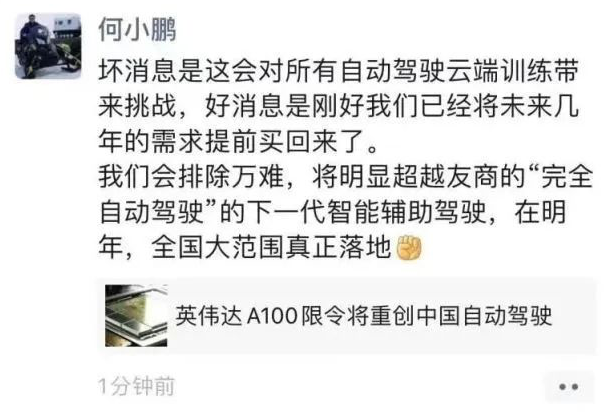

In the domestic market, after entering 2022, there are also a number of car companies CEO said publicly that they are facing the problem of "lack of core". Previously, Huawei smart car solution BU CEO Yu Chengdong also pointed out in an interview with the media that he had just entered the automotive field and was not familiar with and did not know the supply of the industry. It was not clear that the whole industry had such a serious lack of core. A chip from 10 yuan to 20 yuan was fried to 2500 yuan, while a car would use 9 such chips, which was too expensive to accept such a high speculation price and would rather sell less. In addition, Xiaopeng Chairman CEO he Xiaopeng also posted the status of lack of chips in the supply chain team on personal Weibo. At the same time, he Xiaopeng stressed that in fact, most of the missing chips are cheap chips, rather than those that are concerned by many people to start a business or are very expensive. At the Guangdong-Hong Kong-Macau Greater Bay Area International Automobile Expo, he Xiaopeng also directly expressed the problem of skyrocketing chip prices. cheap chips with an original purchase cost of only a few yuan were fried to several thousand yuan, such as chips quoted at 3000, 2700, and 2500 yuan. but the actual purchase cost is only 3.50 yuan, 7 yuan, in this environment, there is no way to do procurement. Not long ago, he Xiaopeng even said bluntly: "chips have been hoarded in advance."

For automakers and automakers, the lack of any key chips in the manufacturing process will lead to normal production and delivery of vehicles. As of Sept. 11, the global auto market has lost about 3.232 million vehicles due to chip shortages, according to AFS, an automotive industry data forecasting company. AFS predicts that the cumulative production reduction in the global car market will climb to 4.0712 million by the end of this year. Sam Fiorani, vice president of global automotive forecasting at AFS, said the chip shortage was expected to last until at least mid-2023. At present, the automobile industry is still in a state of shortage of key components, and people in the industry expect the shortage of chips to continue in the short term, which is not expected to be alleviated until the second half of this year or 2023.

Welcome to subscribe to the WeChat public account "Automotive Industry Focus" to get the first-hand insider information on the automotive industry and talk about things in the automotive circle. Welcome to break the news! WeChat ID autoWechat

Views: 0

*The comments in the above article only represent the author's personal views and do not represent the views and positions of this website. If you have more insights, please feel free to contribute and share.

© 2024 AutoBeta.Net Tiger Media Company. All rights reserved.