In addition to Weibo, there is also WeChat

Please pay attention

WeChat public account

AutoBeta

2024-11-21 Update From: AutoBeta autobeta NAV: AutoBeta > News >

Share

AutoBeta(AutoBeta.net)09/23 Report--

Toyota announced on its website that due to a shortage of semiconductors and other components, the spread of the COVID-19 epidemic and stagnant logistics, global production in October was about 800000 vehicles, 100000 fewer than previously expected. however, Toyota stressed that its production target of 9.7 million vehicles for the whole fiscal year 2022 (April 2022-March 2023) remains unchanged.

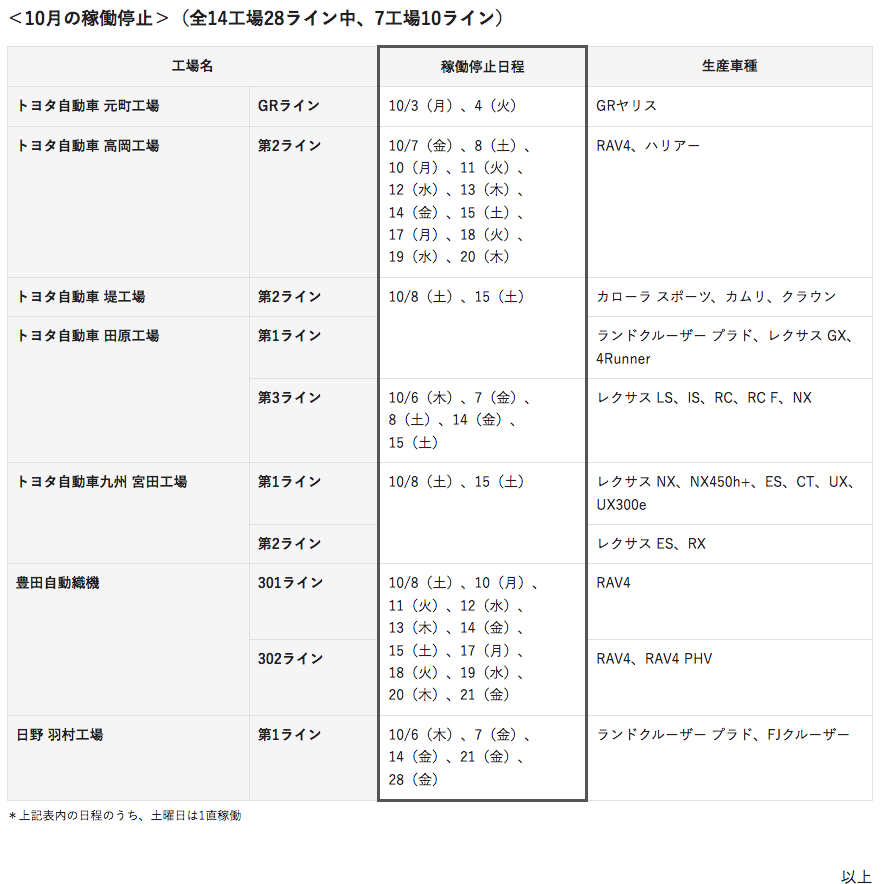

According to Toyota's latest shutdown plan, production will be suspended at 7 of 28 production lines at Toyota's 14 factories in its home market in October. Among them, Toyota Takaoka factory and Toyota automatic loom stop production for the longest 11 days; Toyota Woncho plant, Toyota embankment factory and Toyota Kyushu Miyada plant have the shortest shutdown time of 2 days, the affected models include RAV4, Camry, Lexus LS, IS, RC, RC F, NX, GX, ES, RX and so on. As a result, Toyota cut global production by 100000 to 800000 in October.

According to the original plan, Toyota planned to produce an average of 850000 vehicles per month from August to October, but in view of the failure to achieve production capacity in some months due to the chip shortage and supply chain disruptions in the first half of this year, Toyota raised its average production plan from September to November to 900000 vehicles, including about 250000 in Japan's domestic market and 550000 in overseas markets. According to Toyota's latest global production plan of about 800000 vehicles in October, it means that Toyota's production capacity in October has been cut by 100000 vehicles. At the same time, Toyota said it planned to have an average global monthly production capacity of 850000 vehicles in the period from October to December. Toyota explained that the global average monthly capacity of 850000 vehicles from October to December was based on careful confirmation of parts supply and supplier staffing and equipment capability. however, given the many uncertainties in the general environment, future production capacity is difficult to predict, but will do its best to curb sudden production cuts.

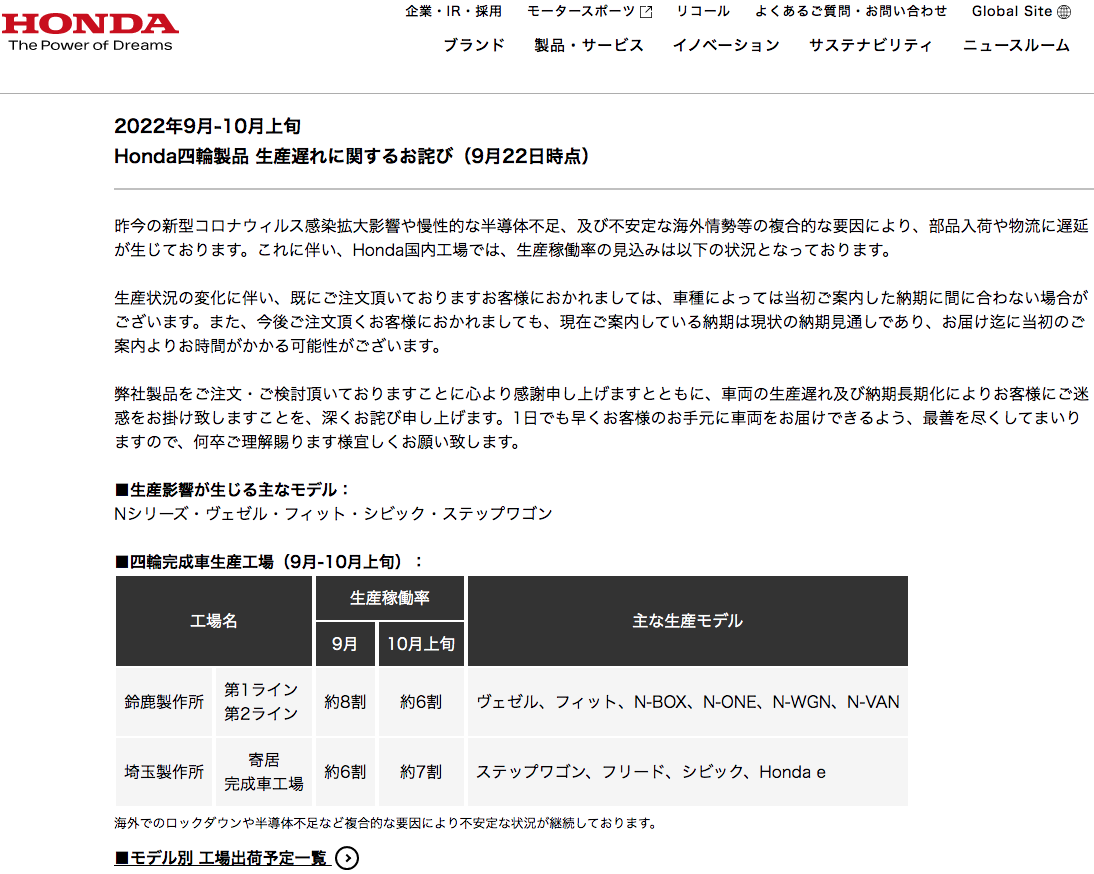

On the same day, Honda, a Japanese car company, also announced on its website that Honda was also facing production cuts due to a long-term shortage of semiconductors and other components, the spread of the COVID-19 epidemic, and stagnant logistics. Honda said two production lines at the Suzuki plant in western japan would cut production by about 40% in early October, while the plant in Saitama prefecture north of Tokyo would also cut production by about 30% in early October. Affected by this, Honda's production of a number of models, including Feido, Civic, Vezel SUV, Stepwgn minivan and so on, has been affected to varying degrees.

Honda also said that due to the epidemic and semiconductor shortage caused by parts reception and logistics delays, in the rest of this month, Suzuki Prefecture factory and Saitama Prefecture plant will reduce production by about 20% and 40%, respectively. Suzuki Prefecture plant capacity increased from 70% previously announced to 80% capacity, but Honda pointed out that due to changes in production conditions, users who have placed orders may not be able to meet the originally announced delivery date. Depending on the model For users who order later, the currently announced delivery date is the current delivery date forecast, and the delivery time may be longer than expected.

With the exception of Japanese car companies, the world is actually plagued by supply chain shortages in the automobile industry, and in order to cope with supply chain shortages, many car companies have to announce production cuts, at the same time, upstream suppliers make decisions to raise product prices.

On Sept. 19, Ford announced that it expected its third-quarter costs to increase by $1 billion because of supply chain problems. Ford said that supply chain problems led to a shortage of parts, affected by the supply chain impact, Ford about 40 to 45000 vehicles could not be delivered to dealers in time. Adam Jonas, an analyst at Morgan Stanley, points out that it is only a matter of time before suppliers start passing on costs.

Not long ago, 木拉提 Aksel, head of procurement for Volkswagen's board, said: "the chip shortage will not end in 2023 and Volkswagen is preparing for a 'new normal' of supply chain disruption. Judging from the situation in the supply chain over the past two years, this is the new normal. As geopolitical problems arise, it will become more complex and challenging. " It is reported that in the short term, Volkswagen plans to increase inventory in warehouses and transportation channels such as ships and trains, while medium-term solutions may include shifting production to other regions in order to prevent parts shortage from affecting production capacity.

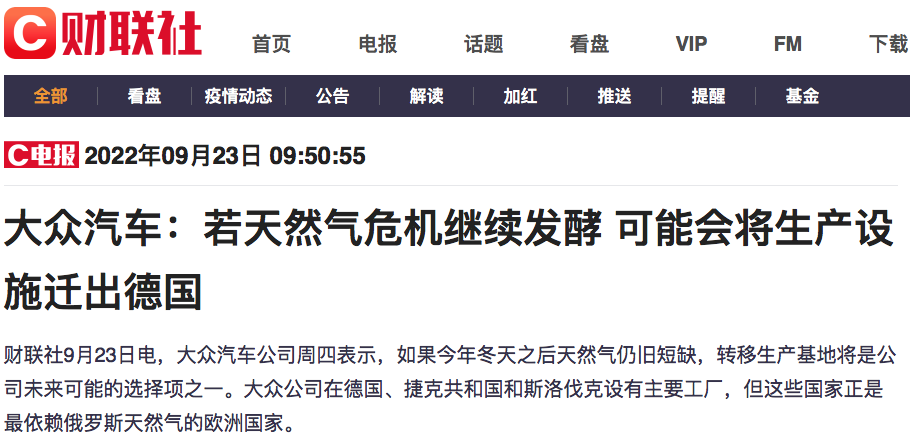

In addition to supply chain pressure restricting Volkswagen's capacity, a senior Volkswagen executive said in an interview on September 22 local time that if Germany could continue to replenish its natural gas reserves, Volkswagen may be able to maintain production for the next five to six months, but rising energy prices and unstable supply chain networks pose risks to its global production. Volkswagen pointed out that the current Russian gas supply outage does not affect its production, but next June may face the problem of natural gas shortage. Of course, Volkswagen also made a relative response, Volkswagen said: "if there is still a shortage of natural gas after this winter, the transfer of production base will be one of the possible options for the company in the future."

A few days ago, according to Reuters, automaker Stellantis and some French Renault factories were also forced to stop production because of chip shortages. Among them, two Renault plants in Castilla and Leon, Spain, temporarily suspended production, one of which was completely closed on Sept. 17, and the other cancelled shifts in the next few days; while Stellantis's plant in Vigo, northwest Spain, has cancelled night shifts from September 17 to 18. In the past, the two car companies have suffered a number of production suspension problems.

In the domestic market, including Huawei smart car solution BU CEO Yu Chengdong and Xiaopeng Chairman CEO, they have publicly said that they are facing the problem of "lack of core". In response to the shortness of the chip, he Xiaopeng even said: "the chip has been hoarded in advance."

Judging from the current situation of some automobile companies, although the problem of "core shortage" has been alleviated somewhat after entering 2022, it still continues and affects the global automobile production of some automobile companies.

According to auto industry data forecasting company AFS, as of September 18, the global auto market has lost about 3.2801 million vehicles due to chip shortages, including about 27600 cars in North America last week and 20200 cars in China. Europe, South America, the Middle East, Africa and the rest of Asia have not cut production due to lack of cores, that is, North America and China were the two regions with the biggest production cuts in the world last week. AFS predicts that the cumulative production reduction in the global car market will climb to 4.1191 million by the end of this year. Sam Fiorani, vice president of global automotive forecasting at AFS, said the chip shortage was expected to last until at least mid-2023. At present, the automotive industry is still in a state of shortage of key components, and people in the industry expect that the problem of chip shortage will continue in the short term and is not expected to ease until next year.

Welcome to subscribe to the WeChat public account "Automotive Industry Focus" to get the first-hand insider information on the automotive industry and talk about things in the automotive circle. Welcome to break the news! WeChat ID autoWechat

Views: 0

*The comments in the above article only represent the author's personal views and do not represent the views and positions of this website. If you have more insights, please feel free to contribute and share.

© 2024 AutoBeta.Net Tiger Media Company. All rights reserved.