In addition to Weibo, there is also WeChat

Please pay attention

WeChat public account

AutoBeta

2024-11-21 Update From: AutoBeta autobeta NAV: AutoBeta > News >

Share

AutoBeta(AutoBeta.net)10/03 Report--

Since the outbreak of the epidemic, due to the tension of the global supply chain, rising raw materials and logistics costs and other external factors, the interruption of new car production has become a common topic in the automotive industry, especially in Japanese car companies. After entering 2022, Toyota, Honda, Mazda, Mitsubishi Motors, Subaru, Nissan and other car companies have encountered production suspension or production reduction problems. Take Toyota as an example. Since March this year, Toyota has frequently encountered production stoppage and production reduction due to the above factors. In June, Toyota was forced to cut production at its front and back factories three times, and its production capacity was reduced from the original 950000 to 750000 vehicles, with a cumulative production reduction of about 200000 vehicles.

According to the latest Nikkei News, data released by eight Japanese car companies show that global production of eight Japanese passenger car companies, including Toyota, rose 31 per cent in August from a year earlier to 2.009 million vehicles, the first time that they exceeded 2 million vehicles since 2019. Although this figure is down 5 per cent from August 2019 compared with the same period last year, it has gradually returned to the level of production before the COVID-19 epidemic.

In terms of global production, all eight companies produced more cars than last year, with Nissan's production in Japan and the US rising 9 per cent to 288000; Honda up 27 per cent to 347000; and Mazda tripling to 92000. The marked increase is due to retaliatory growth caused by a decline in production capacity caused by stagnant production by Japanese carmakers in the same period last year. In addition, as one of the important markets for Japanese car companies, the output of the region has also increased. According to the report, both local and overseas production increased, with the combined production of eight Japanese car companies up 22 per cent year-on-year to 551000 vehicles, and overseas markets up 34 per cent to 1.457 million vehicles.

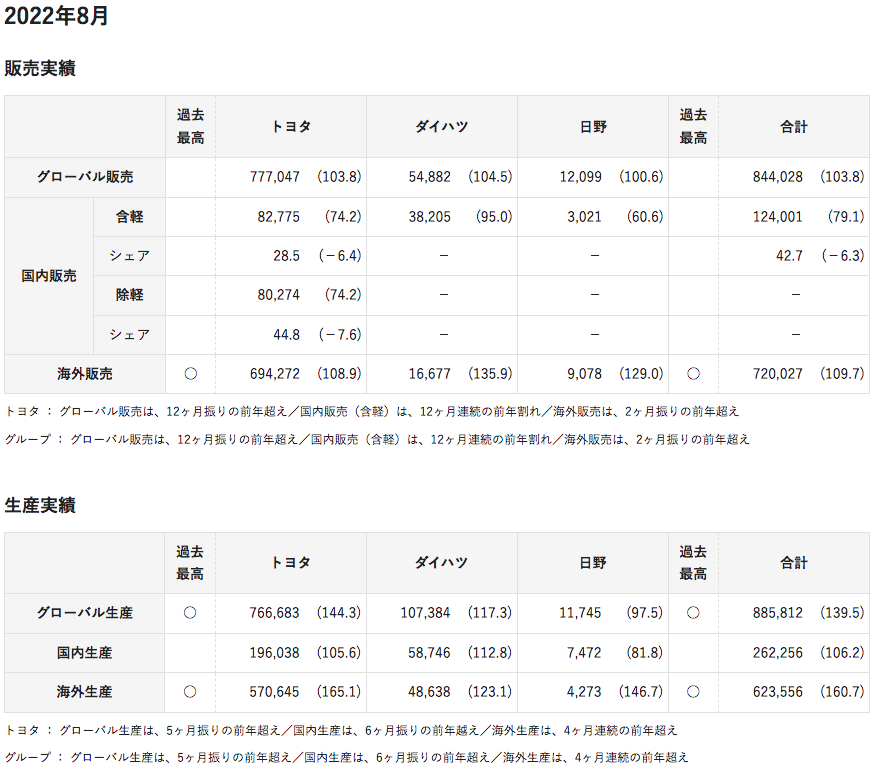

In Toyota, for example, global production rose 44.2 per cent year-on-year to 766683 vehicles in August 2022, the first increase in four months, with domestic production rising 5.6 per cent to 196038 vehicles and overseas markets up 65.0 per cent to 570645 vehicles.

It should be noted that although the production of eight Japanese car companies increased in August compared with the same period last year, Japanese car companies are still negatively affected by the shortage of semiconductors and rising prices of raw materials. at present, the supply of spare parts is still interfering with the normal operation of the production capacity of Japanese car companies. At the end of last month, Toyota and Honda all announced production cuts or stoppage announcements.

Toyota announced on September 22nd that it planned to produce an average of 850000 vehicles a month worldwide from October to December, with global production of about 800000 vehicles in October, 100000 fewer than previously expected, affected by a shortage of semiconductors and other components, the spread of the COVID-19 epidemic and stagnant logistics. Toyota explained that the global average monthly production capacity of 850000 vehicles from October to December was based on careful confirmation of parts supply and supplier personnel structure and equipment capacity, but considering many uncertainties in the general environment, future production capacity is difficult to predict, but will do its best to curb sudden production cuts. Honda also announced on its website that Honda is also facing production cuts due to a long-term shortage of semiconductors and other components, the spread of the COVID-19 epidemic and stagnant logistics. Honda said two production lines at the Suzuki plant in western japan would cut production by about 40% in early October, while the plant in Saitama prefecture north of Tokyo would also cut production by about 30% in early October. Due to changes in production conditions, Honda's new car delivery time may be longer than expected.

Due to the shortage of semiconductors and other parts, a number of Japanese car companies have also faced "difficulties in delivering new cars". For example, Nissan Leaf leaf and Nissan Sakura currently take up to six months to deliver, of which Nissan Leaf leaf delivery time is about two months longer than the same period last year. Honda announced on September 2nd that the release of Honda's new SUV model ZR-V was postponed due to global semiconductor shortages and supply chain chaos. Honda said that the release of the ZR-V, which was scheduled to launch in the autumn, will be postponed to the spring of 2023, and Honda will give priority to the delivery of existing models, but the pre-sale time for ZR-V will still start from September 8, so that Honda can deliver the car when it goes on sale next spring. In order to speed up the delivery of new cars, Toyota even launched "recommended optional models" measures to improve production efficiency and shorten the delivery time. Among them, the shortest delivery time of "recommended optional models" is 2-3 months, and the longest will be delivered before April 2023, while other vehicles other than "recommended optional models" need to be postponed to after April 2023. The delivery time is more than 8 months.

Capacity suppression is also directly fed back to the sales terminal. Take the global sales of the Japanese system in the first half of this year as an example. In the first half of this year, the total global production of eight Japanese passenger car manufacturers, including Toyota, Suzuki, Honda, Nissan, Subaru, Mitsubishi and Mazda, was 11.55 million vehicles, down 6% from the same period last year. Global sales were 11.63 million, down 11.4% from the same period last year, a year-on-year decline in the past two years. Specific to the major brands, most car companies also showed a downward trend, including Toyota's global sales down 6.1% to 4.69 million vehicles, Honda down 19.5% to 1.9 million vehicles, Nissan down 23.9% to 1.67 million vehicles, Mazda down 22.0%, Subaru down 19.3%, Suzuki up 2.0% to 1.46 million vehicles, and Mitsubishi Motors up 0.9%.

For Japanese car companies, they are still facing the problem of insufficient production capacity. Subaru's chief financial officer Seiji Mizumi said: "limited production is still Subaru's biggest obstacle, if we can produce more cars, it will bring more sales." The Japanese Federation of Automobile sales Associations and the National Federation of Mini-vehicle Associations also pointed out that the shortage of semiconductors and the difficulties in purchasing parts caused by epidemic control will have an impact on new car sales due to the stagnation of production by Japanese automakers.

Auto Forecast Solutions, the global auto forecast database, expects global car production to be cut by more than 4.2 million vehicles this year, but the chip shortage has improved compared with last year, especially in the Chinese market. According to the data, the cumulative reduction in global automobile production in 2021 is 8.934 million, of which the Chinese market has reduced production by more than 1.6 million. According to the latest data from AFS, as of September 25, due to the shortage of chips, the global auto market has lost about 3.3768 million vehicles this year, of which only 166700 have been reduced in China. Chen Yudong, president of Bosch China, said: "the current chip shortage has caused an imbalance between the semiconductor industry and automotive companies, resulting in a basic shortage of 300000 controllers a month, resulting in many companies unable to complete the task." The industry expects the impact of the lack of core on the automotive industry to continue at least until the middle or end of next year.

Welcome to subscribe to the WeChat public account "Automotive Industry Focus" to get the first-hand insider information on the automotive industry and talk about things in the automotive circle. Welcome to break the news! WeChat ID autoWechat

Views: 0

*The comments in the above article only represent the author's personal views and do not represent the views and positions of this website. If you have more insights, please feel free to contribute and share.

© 2024 AutoBeta.Net Tiger Media Company. All rights reserved.