In addition to Weibo, there is also WeChat

Please pay attention

WeChat public account

AutoBeta

2024-11-17 Update From: AutoBeta autobeta NAV: AutoBeta > News >

Share

AutoBeta(AutoBeta.net)10/23 Report--

Recently, according to media reports: due to the global semiconductor shortage, Toyota Motor expects its annual output to be lower than the original target. Toyota also said it would suspend 11 production lines at eight factories in Japan next month for two to nine days, and the shutdown of 11 production lines would also affect production of Corolla, RAV4, Yaris and other models. A Toyota spokesman said the company was assessing the impact on future production and would announce revised production targets once the outlook became clearer.

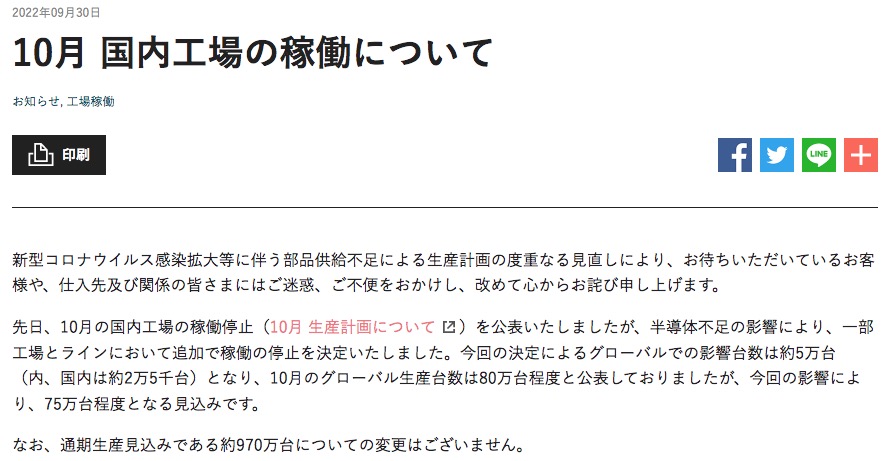

It is worth noting that Toyota has adjusted its monthly output several times in recent years due to chip shortages and the impact of the epidemic. On September 30, Toyota Motor Watch lowered its global production plan for October by about 50,000 vehicles due to factors such as epidemic situation and shortage of parts supply, spread of Xinguan epidemic situation and logistics stagnation. After adjustment, the global production plan for October will be lowered from 800,000 vehicles announced earlier to 750,000 vehicles. Toyota Motor Corp. said on Sept. 22 it plans to produce about 800,000 vehicles worldwide in October, about 100,000 less than its average monthly production plan, due to a semiconductor shortage. Toyota's October production plan was 150,000 fewer vehicles than originally planned.

However, Toyota said in announcing the October production target cut that the production cut would not affect the full-year production plan and that the capacity target of 9.7 million vehicles for fiscal year 2022 (April 2022-March 2023) remained unchanged. Unexpectedly, Toyota once again had to lower its annual production target because of the shortage of cores. According to the plan, Toyota plans to produce about 9.7 million vehicles in fiscal year 2022 (April 2022-March 2023). Since entering this fiscal year, Toyota has encountered many shutdown and production reduction problems. In June this year, Toyota lowered its production capacity plan three times, from 950,000 originally planned production capacity to 750,000 vehicles, with a cumulative production reduction of about 200,000 vehicles. Despite this, Toyota has repeatedly stressed that it will maintain its annual production target of 9.7 million vehicles.

In fact, Toyota's output has been low since last year. In March this year, due to semiconductor shortages, supplier system failures and earthquake shutdowns. On March 1, Toyota suspended operations at all of its factories in Japan, including 28 production lines at 14 plants. On March 16, Toyota suspended production for three days from March 21 to 23 at 11 factories and 18 production lines due to a massive power outage in the relevant areas caused by a magnitude 7.4 earthquake near Fukushima Prefecture, Japan.

On April 18, Toyota Motor announced again that several factories in Japan would stop production for several days in May and reduce global production by 10% to 750,000 units in May. On May 10, Toyota cut global production for May to 700,000 units. Toyota said: Affected by the Shanghai epidemic and supply chain shortage, Toyota's factories in Japan will be shut down for several days from May 16 to 21, including the Takaoka plant in Toyota City, Aichi Prefecture and the Tahara plant in Tahara City, Aichi Prefecture, with a total of 8 factories and 14 production lines, including Toyota Crown, bZ4X, C-HR, RAV4 and Lexus NX.

From Toyota's several production cuts and adjustments, all of them have a certain impact on its sales volume. According to relevant data, from April to August this year, Toyota's global cumulative output was 3593807 vehicles, accounting for 37.0% of the annual production capacity target of 9.7 million vehicles. This figure also means Toyota needs to complete the remaining 6,106,200 vehicles in the next seven months. According to specific data, the global automobile output in April, May, June, July and August 2022 is 692259 vehicles, 634940 vehicles, 793378 vehicles, 706547 vehicles and 766683 vehicles respectively.

Toyota is still affected by supply chain disruptions caused by chip shortages and the new crown pneumonia epidemic, as Toyota expects its annual production to fall below its original target. And when the chip shortage problem can be alleviated, many industry insiders also expressed their views. Stellantis CEO Tang Weishi recently said that the chip shortage is expected to ease by the end of 2023, and Volkswagen Group Chief Financial Officer Arno Antlitz said that the chip shortage is expected to continue until 2024. In addition, according to the latest data from the automotive industry data forecasting company AFS, as of October 9, due to the shortage of chips, the global automotive market has reduced production by about 3.5371 million vehicles in 2022. AFS estimates that the cumulative reduction in the global auto market will rise to 4,363,500 units by the end of this year.

Welcome to subscribe to the WeChat public account "Automotive Industry Focus" to get the first-hand insider information on the automotive industry and talk about things in the automotive circle. Welcome to break the news! WeChat ID autoWechat

Views: 0

*The comments in the above article only represent the author's personal views and do not represent the views and positions of this website. If you have more insights, please feel free to contribute and share.

© 2024 AutoBeta.Net Tiger Media Company. All rights reserved.