In addition to Weibo, there is also WeChat

Please pay attention

WeChat public account

AutoBeta

2024-11-22 Update From: AutoBeta autobeta NAV: AutoBeta > News >

Share

AutoBeta(AutoBeta.net)11/27 Report--

According to the latest data from auto industry data forecasting company AutoForecast Solutions (hereinafter referred to as "AFS"), as of November 20, due to a shortage of chips, the global auto market has lost about 4.0551 million vehicles this year. AFS predicts that the cumulative production reduction in the global car market will climb to 4.4228 million by the end of this year. Although the shortage of chips has eased somewhat this year, car companies still need to adjust their production plans to solve the problem. At present, Honda Motor and Toyota Motor, the two major Japanese manufacturers, have announced that they will continue to cut production in December because of a shortage of car chips.

Honda is again facing production cuts due to a shortage of semiconductors and other components, the spread of COVID-19 's epidemic and stagnant logistics, Honda announced on its website on Nov. 25. Honda said its plant in Saitama prefecture, north of Tokyo, would cut production by about 30% in early December, while two production lines at the Suzuki plant in western japan would maintain their original production plan. Affected by this, Honda Civic, Stepwgn2 model delivery needs to wait more than half a year. Honda noted that due to delays in receiving and logistics of spare parts caused by outbreaks and semiconductor shortages, as well as changes in production conditions, users who have placed orders may not be able to meet the initially announced delivery date, depending on the model; for users who order later, the currently announced delivery date is the current delivery date forecast, and the delivery time may be longer than expected.

Toyota also announced on its website that due to a shortage of semiconductors and other components, the spread of the COVID-19 epidemic and stagnant logistics, Toyota produced about 750000 vehicles worldwide in December (about 250000 in Japan's domestic market and 500000 in overseas markets), down about 6% from December last year. Toyota had previously said that it had planned to produce an average of about 850000 vehicles a month from October to December, but the latest December production plan was about 100000 vehicles lower than expected. In addition, due to a continuing shortage of semiconductor chips, Toyota announced that its global production target for the current fiscal year (April 2022-March 2023) was lowered from 9.7 million to 9.2 million.

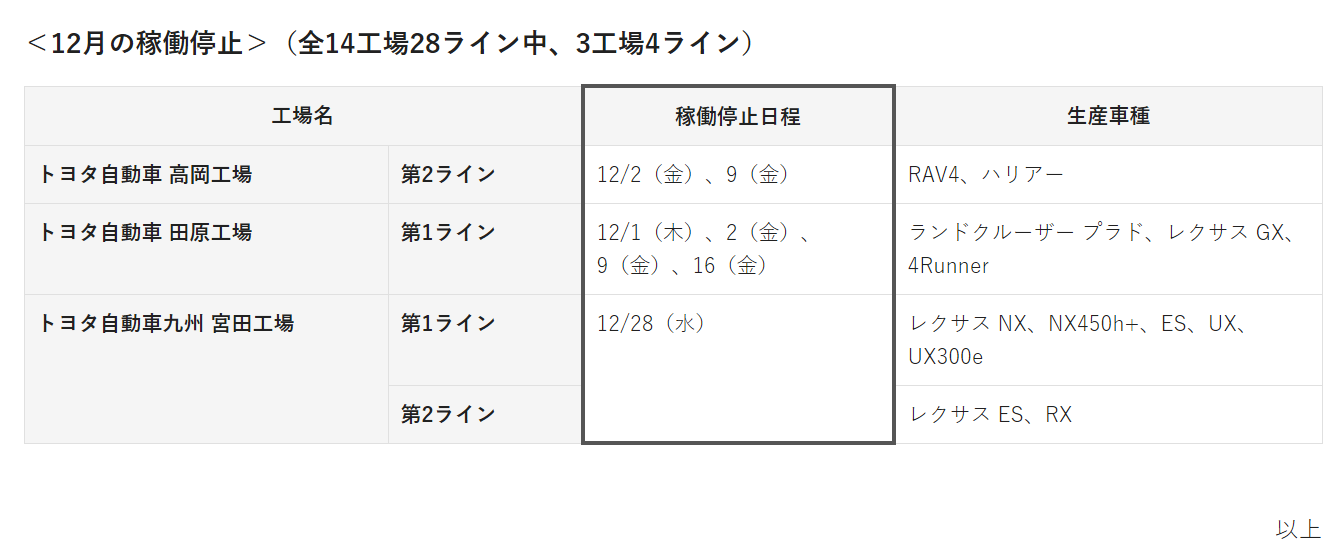

According to Toyota's latest shutdown plan, of a total of 28 production lines in Toyota's 14 factories in Japan in December, 4 production lines in 3 factories will be suspended for 1-4 days. Among them, the longest shutdown time of a production line at Toyota's Taiyuan plant is 4 days; one production line at Toyota's Takaoka plant is suspended for 2 days; and two production lines at Toyota's Kyushu Miyada plant are suspended for 1 day respectively. Models affected by this include RAV4, Land Cruiser, Prado, Lexus GX, 4Runner, NX, NX450h+, ES, UX, UX300e, ES and RX.

For Japanese car companies, the current global shortage of parts, the epidemic and the conflict between Russia and Ukraine and other uncertain factors continue to have a negative impact on Japanese car companies, while the decline in production capacity and rising prices may put pressure on the overall sales of Japanese car companies. Of course, with the exception of Japanese car companies, the whole world is plagued by supply chain shortages in the automobile industry to varying degrees. In order to deal with supply chain shortages, other car companies have also taken measures to reduce production or delay delivery.

Automaker JLR will cut production at its plants in Solihull and Halewood by next spring because of a lack of cores, the BBC reported on November 26th. The affected models include Jaguar F-Pace, Land Rover Discovery Sport and so on. Jaguar Land Rover said in a statement that it would continue to actively manage the mode of operation of its manufacturing plants, while the industry is experiencing continued disruptions in the global semiconductor supply chain. "with the new agreement with semiconductor partners coming into effect, results are expected to continue to improve in the second half of the year, enabling us to build and deliver more vehicles for our customers," Jaguar Land Rover said. "

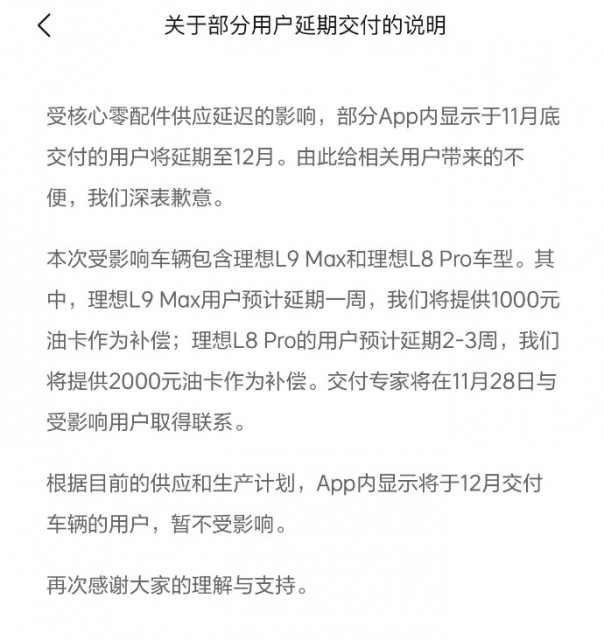

In the Chinese market, ideal Automobile, the new force of car building, announced today that due to the delay in the supply of core parts, some users in App who indicated that delivery at the end of November would be postponed to December. The announcement shows that the affected vehicles include ideal L9 Max and ideal L8 Pro models. Among them, the ideal L9 Max users are expected to extend by one week, and the ideal L8 Pro users are expected to delay by 2-3 weeks. Ideal officials will compensate 1000 yuan and 2000 yuan respectively for fuel cards for users who order these two models. From the ideal car postponement announcement, the delay in the supply of core parts does not have a great impact on the ideal car, ideal car said that the model delivered in December will not be affected.

Mike Hawes, chief executive of the British Association of Automobile Manufacturers and traders (SMMT), said: "there is indeed a shortage in the supply chain, the most obvious is semiconductors, resulting in very unstable production levels." Tang Weishi, chief executive of Stellantis, said in October that the tight supply of semiconductors was expected to last until the end of next year, while Thomas Ingenlath, chief executive of Jixing, also expected the shortage of parts and components to continue into next year. According to the latest AFS data, production in China has been cut by 172900 vehicles so far this year due to lack of cores, but Chinese car production has been relatively less affected by the chip crisis compared with more than 1 million in North America and Europe.

Welcome to subscribe to the WeChat public account "Automotive Industry Focus" to get the first-hand insider information on the automotive industry and talk about things in the automotive circle. Welcome to break the news! WeChat ID autoWechat

Views: 0

*The comments in the above article only represent the author's personal views and do not represent the views and positions of this website. If you have more insights, please feel free to contribute and share.

© 2024 AutoBeta.Net Tiger Media Company. All rights reserved.