In addition to Weibo, there is also WeChat

Please pay attention

WeChat public account

AutoBeta

2024-11-22 Update From: AutoBeta autobeta NAV: AutoBeta > News >

Share

AutoBeta(AutoBeta.net)07/17 Report--

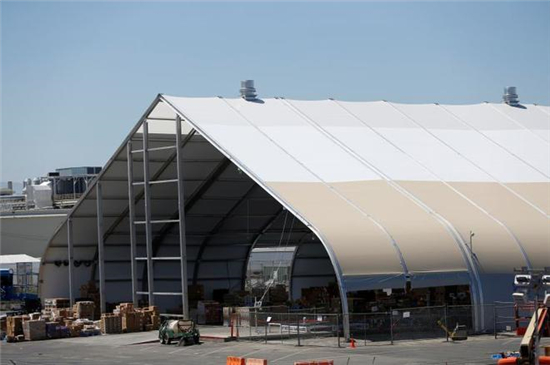

According to relevant media reports, Tesla recently proposed to set up tents to assemble cars in June last year in order to improve the efficiency of car mass production on the premise of cost control. Recently, Tesla was exposed again that Tesla began to "take shortcuts" in order to increase the output of Model 3. The staff of the open-air tent said that in order to achieve the goal of mass production of the Model 3, they were told by their supervisors to use electronic tape to quickly repair parts such as plastic brackets, while skipping the previously required vehicle testing, all in order to control costs and increase production. But this practice may bring "sequelae" to Model 3, that is, the quality is not up to standard.

It is understood that Tesla built a tent assembly section called GA4 Model 3 in Fremont, California in the spring of 2018, and the tent is produced in three shifts a day, with a production capacity of up to 120 cars per shift, equivalent to 2160 Model 3s in a complete six-day working week. According to employees, during the assembly process, it is easier to break a large number of plastic brackets and housings, which are mainly used to secure key electronic components inside Model 3, while supervisors instruct employees not to replace new parts, but to use vinyl electronic tape to repair them quickly.

As shown in the image above, the white plastic shell controls the connection of the "three cameras" inside the Model 3, which are installed in the windshield of the Model 3, and the broken or loose link may invalidate the safety function of the vehicle. In fact, the plastic shell often cracked during the assembly process, and Tesla's staff handled it by using electronic glue to bring simple treatment and repair. In addition to using electronic tape to quickly repair parts, employees say that in order to save time on the production line, even if they know that the car lacks a small number of small parts such as bolts, nuts and lugs, the car will continue to walk on the production line. I don't want to stop the production line.

(the picture shows the power supply of the terminal board in the right front controller of the Model 3 body, and a nut that was supposed to be used to secure the electrical connection is missing. Tesla said earlier that the end of the GA4 assembly line would check each car to make sure there were no quality problems before it left the factory. Tesla's former and current employees said that with the increase in production of the Model 3, Tesla reduced the "rain test" of the vehicle, and by the end of 2018, Tesla only tested the Model 3 for leaking samples. Since then, even if some employees have found a problem with the polyurethane seal around the Model 3 glass roof, they are reluctant to propose a leak test for the vehicle because they not only lack the experience needed to identify defects, but also waste a lot of time.

On the other hand, the workers in the workshop were tortured by the poor working environment. The workers had asked Tesla's environmental health and safety team to help solve the high temperature, vermin and other problems, but they did not seem to have improved much. In November 2018, when a large-scale forest fire broke out in northern California, Tesla asked employees to work in the tent workshop on time, and did not take the initiative to hand out masks to workshop employees, who had to endure the harsh environment of high temperature and smoke. When the weather became wet and cold, employees said Tesla would provide bright red jackets for GA4 employees last year, but stopped issuing them at the beginning of this year. In addition, if employees use electric heating in the area where the quality of Model 3 vehicles is checked, it will be regarded as a violation. For the "shortcut" behavior revealed by employees, Tesla said that acts such as the use of electronic tape to quickly repair parts in the assembly process are unapproved, and there is no disregard of product quality in order to achieve the target of mass production. Tesla repeatedly stressed that every car produced is subject to strict quality inspection, and there is a special inspection team to track every car, and every car is subject to quality control before it is delivered to the customer. With regard to the working environment of employees, Tesla said that he is working hard to create a safe, fair and interesting working environment. In fact, many employees want to work in the GA4 workshop.

According to production data, Tesla's production figure was 87048 vehicles by the end of June 2019, of which 72531 were Model 3 models. Tesla expects delivery of more than 360000 vehicles this year, of which at least 250000 are Model 3s. From a financial point of view, Tesla's loss in the first three months of this year was one of the worst in history, with a loss of 702 million. However, Musk believes that cost-cutting measures and increased delivery will allow Tesla to turn a loss into profit in the third quarter.

In fact, Tesla's cost-cutting has long been reported before. In order to reduce expenses, a series of incidents have been reported earlier, such as stopping providing free toilet paper to employees and letting employees drive unsold vehicles home for cleaning. However, in order to reduce costs and increase mass production, this practice of "cutting corners" is undoubtedly putting the cart before the horse. Consumers are only interested in the workmanship quality and performance of their products.

Welcome to subscribe to the WeChat public account "Automotive Industry Focus" to get the first-hand insider information on the automotive industry and talk about things in the automotive circle. Welcome to break the news! WeChat ID autoWechat

Views: 0

*The comments in the above article only represent the author's personal views and do not represent the views and positions of this website. If you have more insights, please feel free to contribute and share.

© 2024 AutoBeta.Net Tiger Media Company. All rights reserved.